|

Edward Lowton

Editor |

|

| Home> | Premises management/maintenance | >Doors and curtains | >Automatic high speed doors reduce carbon emissions |

Automatic high speed doors reduce carbon emissions

10 May 2022

The need to keep industrial doors open can come as a challenge for warehouse or manufacturing facilities that are looking to reduce their carbon footprint. But where it isn't practical to keep an entrance closed all day, high-speed automatic doors can help, says Doug Hart

RESEARCH SHOWS that nearly 40% of carbon emissions are produced from the construction of a property, with a further 30% coming from the actual use of the building, that is heating, lighting, air-conditioning and so on.

As buildings such as manufacturing facilities and warehousing are essential to any country’s economy what can be done to reduce carbon emissions from property? While building energy efficient properties is the obvious step, how can this be achieved?

New build is the opportunity to design with climate in mind from day one. But buildings that were built decades ago can still be updated to reduce energy costs. Solar gain through windows can be beneficial, photo voltaic energy panels and other renewable technologies can be retro-fitted such as ground-source heat pumps or biomass boilers. So there are many options which can be retro-fitted.

The day to day operation of a typical warehouse or manufacturing facility does introduce a crucial issue that can undermine the best intentions of occupiers to be climate aware - the ever open industrial door.

Even with the greatest diligence to make a property almost air-tight and energy efficient to the highest standards, manufacturers and warehouse users must have properties that provide access for raw materials and exits for goods. This can mean just one door or dozens if required for loading bays for example.

Perceived as weak points in the efficiency of a building, this is where the high-speed door operates at its ultimate - by reducing air-flow in or out of a building or between one section within a building and another.

Busy facilities inevitably have incoming products for manufacture and outgoing completed goods. Well aware of the loss of heated air and the inflow of unheated air to a building, 40 years ago Newcastle upon Tyne-based Hart Doors Systems built its first automatic industrial door.

Successful testing showed immense potential for this automatic, high-speed, door branded Speedor. Today Speedors can be found throughout the world from the Falklands to Vladivostok, across Africa, the Middle East, Far East and so on. The original concept is now marketed in seven sub-brands such Speedor Super, Speedor Storm and Cleanroom.

Emissions from the operation of buildings recently hit their highest ever level with the building sector accounting for 38% of all energy-related CO² emissions. For many companies, energy consumption is the main contributor to their overall carbon footprint, including heating, cooling, lighting, and operating equipment. The more efficient companies are in their energy use, the greater the reduction in carbon dioxide emissions.

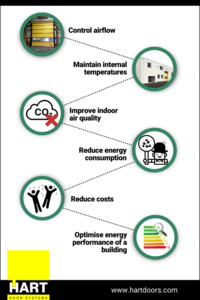

Automatic high-speed doors reduce CO² emissions by playing an integral role in the energy efficiency and environmental impact of a building where heating and cooling systems are the highest producers of energy-related CO² emissions.

Where a door is left open, heating and cooling systems work overtime to maintain internal temperatures at comfortable levels. Where it is not practical to keep an entrance closed all day, the fast open-close operation of high-speed automatic doors allows a steady flow of traffic and at the same time energy consumption.

An efficient, well-insulated and low-maintenance high-speed automatic door application can reduce CO² by reducing draughts, maintaining internal temperatures, optimising traffic flow and create more comfortable working conditions.

Doug Hart is chairman of Hart Door Systems

For more information:

Tel: 01912 140404

- Climate change and the high-speed door

- Door firm re-launches website

- Installation success

- Management changes

- Frequent-use high speed doors

- Roller shutters for train-care depot

- Hart completes Northumberland shutter project

- Metal manufacturer makes door investment

- Doors and project profiles feature in corporate brochure

- Roller shutters for train-care depot