|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Plain bushes |

ARTICLE

Plain bushes

25 January 2013

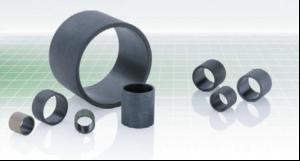

A new range of low friction, maintenance-free plain bushes is suitable for dry-running applications, including high load, high vibration environments. Elgotex INA plain bushes from Schaeffler (UK) are said to provide

A new range of low friction,

maintenance-free plain bushes is

suitable for dry-running

applications, including high load,

high vibration environments.

Elgotex INA plain bushes from Schaeffler (UK) are said to provide a variety of technical advantages that stem from the product's entwined double-layer design.

Each bush comprises two layers of wound (twisted) material. The inner, sliding layer is made from synthetic fibres and PTFE fibres in epoxy resin, while the outer layer comprises continuous glass fibres (filaments) in epoxy resin. This combined, double wound material is stabilised by applying a specific winding angle to the glass fibres, which increases the bush strength. The robust, compact bushes are easy to mount and are maintenance-free.

Elgotex INA plain bushes from Schaeffler (UK) are said to provide a variety of technical advantages that stem from the product's entwined double-layer design.

Each bush comprises two layers of wound (twisted) material. The inner, sliding layer is made from synthetic fibres and PTFE fibres in epoxy resin, while the outer layer comprises continuous glass fibres (filaments) in epoxy resin. This combined, double wound material is stabilised by applying a specific winding angle to the glass fibres, which increases the bush strength. The robust, compact bushes are easy to mount and are maintenance-free.

MORE FROM THIS COMPANY

- Prevention is better than cure

- Innovations for high precision rotary tables and rotary axes

- Bearing range expanded

- Intelligent lubrication system for bearings

- Winners of Wales Quality Award

- Paper explains role of vibration

- Two-in-one bearing lubricator

- Condition monitoring services extended

- Reducing the risk of failure

- For wind turbines

OTHER ARTICLES IN THIS SECTION