|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Storage and containers | >Automated shuttle system |

Automated shuttle system

02 June 2013

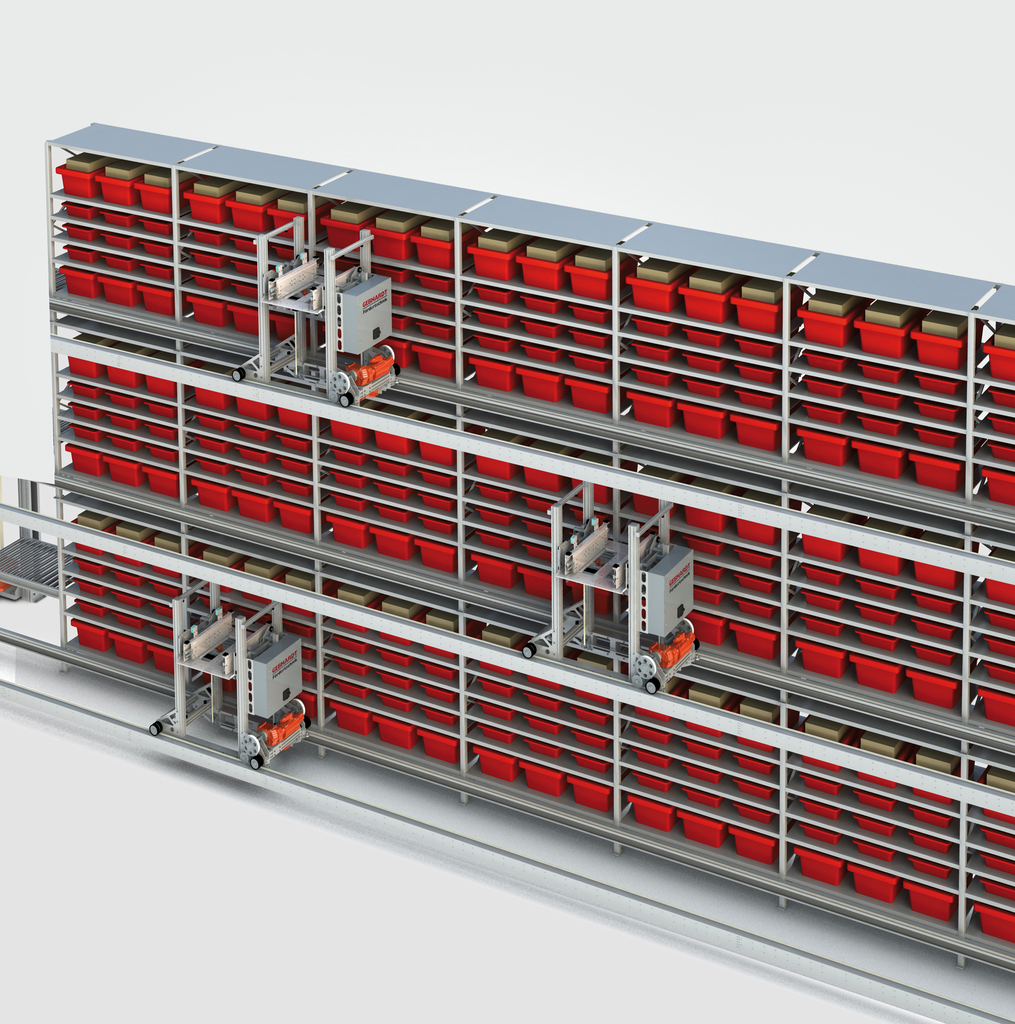

A new high-throughput shuttle system is now available from European Conveyor Systems for handling a wide variety of boxes and pallets in automated warehouses. Developed by Gebhardt Fördertechnik, the system is suitable for single-depth and multi-depth storage.

StoreBiter 300 equipment can handle containers, cardboard boxes and trays weighing up to 50kg in single and multiple depths. The 300 OLS version provides single-level capability, while StoreBiter 300 MLS has a lifting function that allows it to access several levels.

Handling throughputs with the StoreBiter 300 can be maximised by integrating the Gebhardt Dynamic Handover System (DHS).

StoreBiter 500 is designed for handling pallets, stillages and containers weighing up to 1500kg and works according to the first-in first-out principle.

- Automation advances

- Automation cuts costs

- Lift rises to challenge

- Automated handling system helps optimise efficiency and space

- Appointment follows merger

- High capacity conveyor takes little floor space

- Compact yet high-capacity

- Plug-and-play

- IoT-ready intralogistics system

- Compact, high-capacity conveyor solution from ECS