|

Edward Lowton

Editor |

|

Compressor Filtration and Servicing – False Economy?

26 April 2016

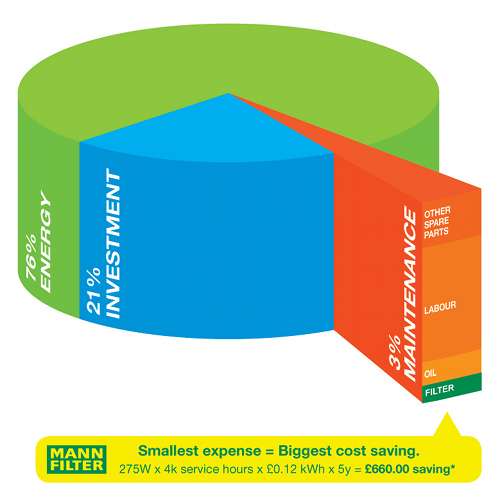

For owners and hirers of compressors and vacuum pumps, the operating costs are often as much of a concern as the initial outlay of the equipment. In fact, energy and maintenance account for 79% of the overall compressor cost compared to 21% initial investment.

In many cases, cost savings are typically centred on the physical components that are replaced during servicing of the compressor or vacuum pump. After all, replacing the disposable filters that are hidden away within the confines of the machine with cheaper, often aftermarket branded parts seems like an easy win to save a few pounds and pence, right?

However, it has been found that optimum OE quality filtration represents less than 0.5% of the overall operating cost of a compressor or vacuum pump. Therefore, does it make more sense to skimp a Penny here and there on cheap, low quality filters, or to potentially save Pounds reducing ENERGY - the highest cost contributor?

For example, genuine OE quality MANN-FILTER air / oil separators can reduce the differential pressure across the filter by at least 30 mbar, saving 275W of energy per hour. And as MANN-FILTER delivers the exact same filtration specification as the OE part fitted on the assembly line, peace of mind is assured.

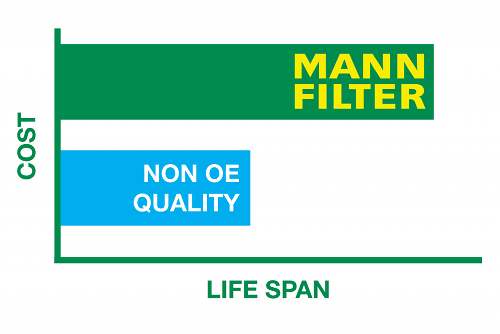

Cheaper filters are of course available, but any savings should not be attributed to the initial purchase price of the filter alone. Cheaper filters are cheaper for a reason, and often have a shorter service life which equates to more frequent service intervals, downtime and thus higher overall cost.

Cost savings then – perhaps not as obvious as first thought?

- No related articles listed