|

Edward Lowton

Editor |

|

OPC-Unified Architecture embedded in valve terminals

15 August 2016

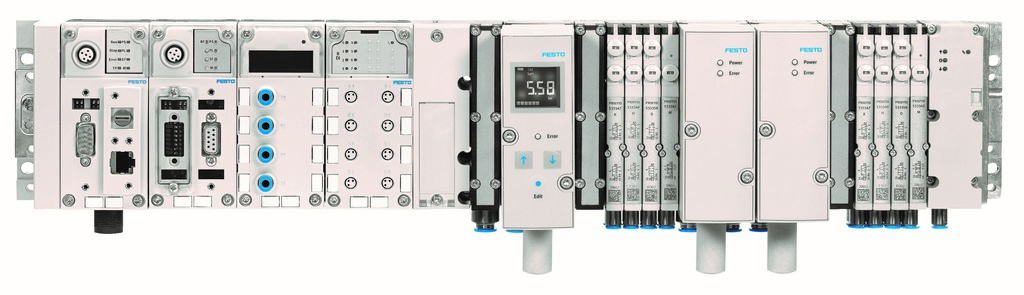

Festo has embedded OPC Unified Architecture, an industrial machine-to-machine communication protocol for interoperability, into its valve terminals, enabling plant managers and engineers to realise the benefits of smart manufacturing and Industry 4.0 principles.

The valve terminals, which control factory and process automation and combine fluid and motion control, can be seamlessly embedded in any Industry 4.0 host environment, supporting factories of the future.

“As we move towards Industry 4.0, communication and engineering standards are absolutely critical. The vision of IoT can only be realised if the communication of the central components is based on a common standard that can fulfil its complex requirements,” says Steve Sands, product manager at Festo. “As OPC-UA is platform and operating system independent, it can provide an open communication solution from the front-end devices, sensors and actuators, or controllers right up to the cloud.”

All Festo’s valve terminals with CPX remote I/O can be extended to include an integrated CODESYS controller. This means that OPC-UA is an available option for Industry 4.0 host environments in all factory automation and process automation applications. OPC-UA is available with the CPX terminal, valve terminals CPX/MPA and CPX/VTSA (OPC UA server), compact controller CECC (OPC UA server) and display and operating unit CDPX (OPC UA client). Festo can also provide mechatronic subsystems as complete customer solutions incorporating OPC-UA.

“OPC-UA is a key standard and in the same way that Industry 4.0 is based on evolution not revolution, we expect to see OPC-UA grow and develop and will be embedding it in many of our products in the future,” adds Sands.

- Pneumatics products available globally

- Festo launches guided pneumatic swivel module

- A study in smart maintenance

- Suitable for food and splash zones

- Piezo valves for laboratory gas handling

- Improving sustainability using controlled proportional pneumatics

- New NAMUR valve range

- Industry 4.0 course

- Simple innovations improve existing pneumatics

- New poppet valves for standard and hazardous applications

- No related articles listed