|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Data capture | >Non-contact signal transmission |

| Home> | Production Engineering | >Quality and tolerance testing | >Non-contact signal transmission |

Non-contact signal transmission

10 April 2017

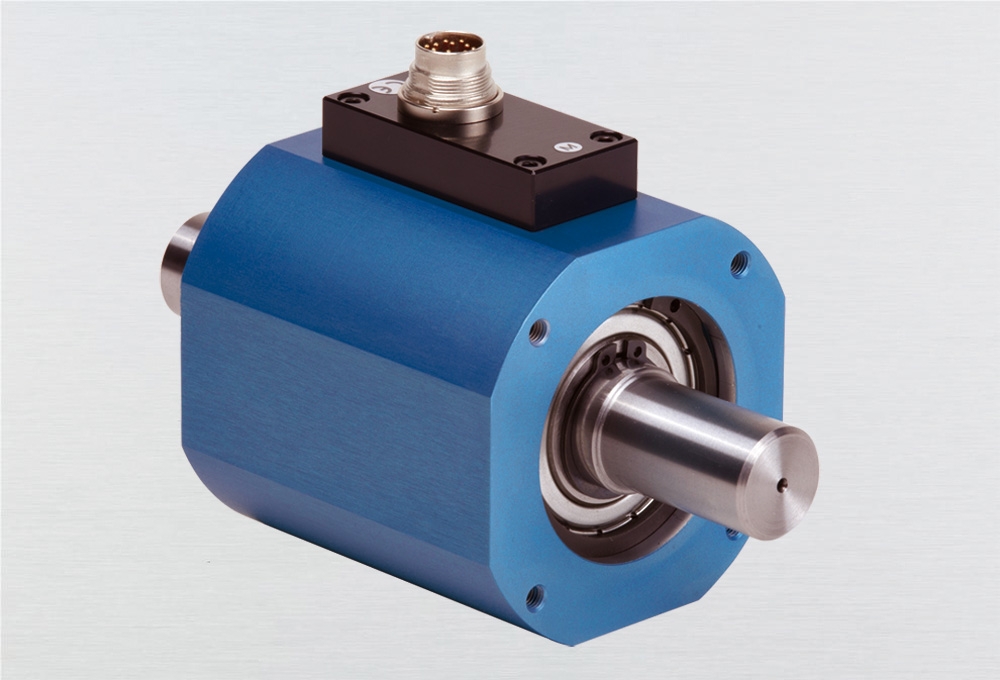

The Kistler Type 4520A sensor for measuring torque on shafts rotating at up to 10,000 rpm uses frequency modulation to transmit the torque signal from the rotating shaft without contact and convert it into an analogue signal. Kistler says this system is more reliable than slip-ring signal transmission which can suffer signal loss due to dirt and wear on the slip-rings.

In the past, contactless sensors have been more expensive than slip-ring types but Kistler says this design costs about the same as inferior slip-ring types.

The sensor has a TTL speed signal at 60 pulses/rev. and an external 100% range check input. Ten units cover the range from 1 to 1000Nm, all with standard ±10 V signal output, and 150% overload capacity. Applications include static and dynamic measurement of torque in assembly and quality control in production and in laboratory applications.