|

Edward Lowton

Editor |

|

Additions made to motive power battery range

09 April 2018

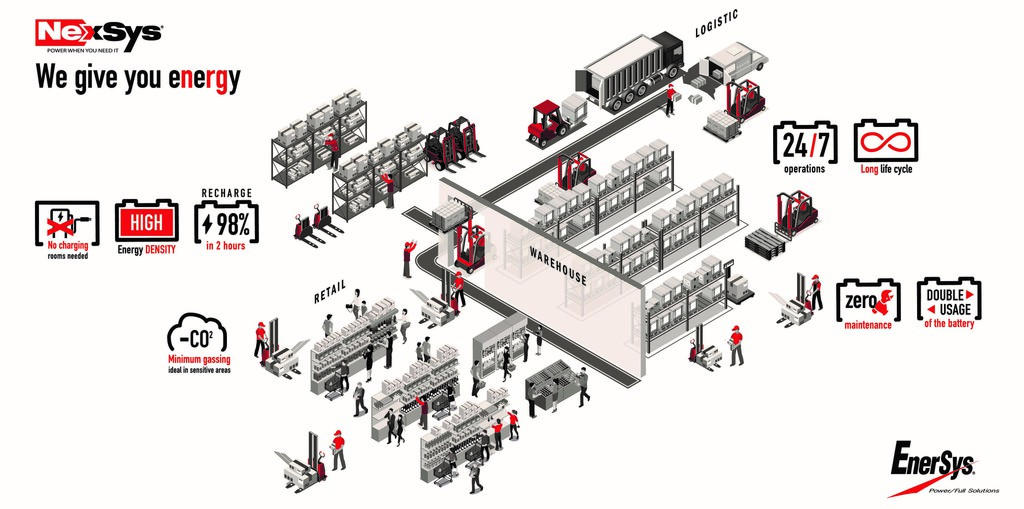

EnerSys has extended its NexSys range of high performance motive power 2V batteries. The range has been expanded with the addition of 6 taller cells that are suitable for higher duty and larger capacity applications, and covers more electric vehicle types and sizes than previously.

The new cells, which are based on Thin Plate Pure Lead (TPPL) technology, are available in heights ranging between 370-675mm and cover C5 capacities from 130 to 980Ah.

“This range extension builds on the already proven benefits of NexSys technology,” comments Martin Walsh, TPPL product manager EMEA at EnerSys. “We’re excited about the new options, which give us access to OEMs manufacturing different types of lift-trucks, and we can also now provide larger-capacity solutions for all of our existing customers.”

TPPL technology is integral to the performance of NexSys motive power batteries. EnerSys says this enables them to lower lifetime operational costs when compared to flooded and gel alternatives.

NexSys batteries are said to have already transformed how many users in logistics, warehouse and production facilities around the world operate their truck fleets, due to features including fast and opportunity charging, zero battery change (ZBC) requirements and long cycle life possibilities.

The increased energy density and opportunity charging capabilities of the batteries means they can be charged during brief periods, such as rest breaks or shift changes, resulting in almost continuous vehicle availability. Productivity for both operators and vehicles is improved, because the need to park a vehicle offline for recharging, or to change its batteries, is eliminated. The batteries are simply recharged on the vehicle, facilitating multi-shift operations.

Maintenance time and effort is also virtually eliminated, as the batteries are sealed units that do not require topping up with water. This prevents risk of injury to operators or damage to facility floors arising from acid spills, while saving the time and effort associated with water top-up. As a result, water costs are reduced. Energy expenditure is also cut due to the batteries’ very low charge factor.

With minimal gassing, vehicles can be charged at or near their point-of-use. Finding space and air-conditioning equipment for charging rooms, as well as vehicle routes to them, becomes unnecessary, as does the need for excessive spare battery stock or lifting equipment. Total cost of ownership is minimised as the batteries are said to have an excellent operating life.

NexSys batteries are available in Standard and Fast configurations so that OEMs and equipment operators can specify the right combination of battery, charger and monitoring system for their precise application and business requirement. The NexSys battery Standard configuration is suitable for low to normal duty applications requiring up to 10 hours of work, with a typical daily energy throughput of 100%, and where an opportunity charge is possible.

The NexSys battery Fast configuration is designed for multi-shift operations, which typically demand up to 16 hours of work. In these applications, EnerSys says the daily energy throughput of around 160% previously required a conventional battery to be changed at 80% DoD; or charged for lengthy periods in situ. The NexSys Fast configuration provides increased flexibility and autonomy. Its specific charging profile allows a rapid recharge in less than four hours from 60% DoD and shorter opportunity charging as often as needed, without damaging the batteries.

- On-demand agv charging

- Savings delivered to logistics firm

- Truck dashboard display gives real time visibility of battery status

- In control of batteries

- Additional 2V batteries

- Whitepaper unravels complex motive power battery choices

- Lower charging

- Efficient charging

- Efficient charging

- Motive power batteries: New technologies deliver benefits

- No related articles listed