|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Cuts through tough residues |

Cuts through tough residues

28 March 2019

A crisp manufacturer is using an Orbitor Eco fast cycle small rotary jet cleaner from The Spray Nozzle People to remove stubborn, sticky residues from 600mm barrels following transfer of flavour concentrates.

Transferring ingredients from barrels and other similar storage vessels is an essential requirement in many food and brewing processes, for example flavour concentrates used in the manufacture of crisps. However, once the liquid concentrates are removed how do you deal with the sticky residues that remain and which are difficult to remove?

Problem

Spinning spray balls previously used to clean the barrels at a large crisp manufacturer were not completing the job which meant a secondary manual clean was required. Whilst the barrels were essentially a very small tank, the tough sticky residue meant that the spinning spray balls, normally suited to these types of small tanks, were simply not up to the job. Another issue was that most rotary jet cleaners were too large and had to high a flow rate to be practical. Also, the set cycle time required by the rotary jet cleaners meant that the 10 minutes or more cleaning cycles to ensure that the jets had reached each part of the tank, were too long.

Solution

The Spray Nozzle People (SNP) provided the crisp manufacturer with an Orbitor Eco fast cycle small rotary jet cleaner. This was trialled on small tanks against several competitor machines. Following the trials the Oribitor was selected as it was judged to provide a better overall clean as well as being a more robust option.

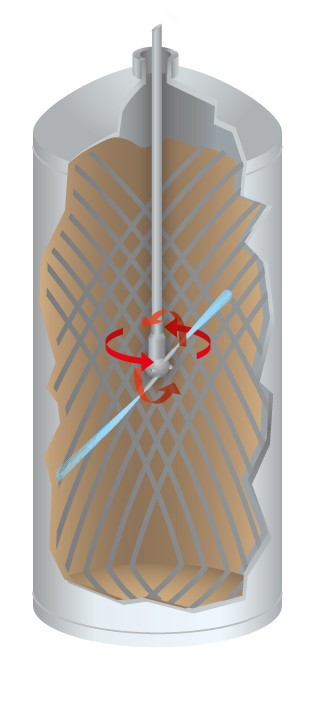

The Orbitor Eco is a new breed of fast cycle jet cleaner that is said to deliver outstanding cleaning power using a fraction of the water compared to other cleaning systems. It rotates quickly through its cleaning cycle, with full cleans achievable in 2 minutes with a flow rate comparable to spinning spray balls.

The impact cleaning of the Eco in this application meant that the barrels were cleaned satisfactorily without the need for a secondary manual clean saving the company time and money.

The Oribtor Eco is designed to provide optimum efficiency, enabling up to 95% water savings (depending on the application) with fast cycle times of between 2 to 10 minutes. It operates on low pressures of 1 to 10 Bar and with low flows of 45 to 150 lit/min and thanks to its small, compact design, fits openings from 10 to 85mm.

More details at: http://www.spray-nozzle.co.uk/orbitor-eco