|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Monitoring and targeting | >Two know more than one |

Two know more than one

21 November 2018

Combining two devices using two different temperature measurement technologies, Fluke Process Instruments can provide the glass industry with information on high-value applications such as float glass manufacturing, glass tempering, and windshield forming and laminating.

Temperature profiling runs with a data logger enable operators to quickly optimise furnace settings for new products and to identify problems with burners or airflow. They are complemented by a thermal imager installed at the furnace exit for 100% production monitoring and traceability.

Datapaq Furnace Tracker profiling systems travel through heat-treatment and quench processes. They record product temperature curves via up to 20 thermocouples cemented to the glass pane. These industry-specific profiling systems consist of a data logger, a thermal barrier, and software with advanced analysis, reporting, and archiving functions. The manufacturer offers a large range of thermal barriers and will advise customers on which system set-up to use for their applications.

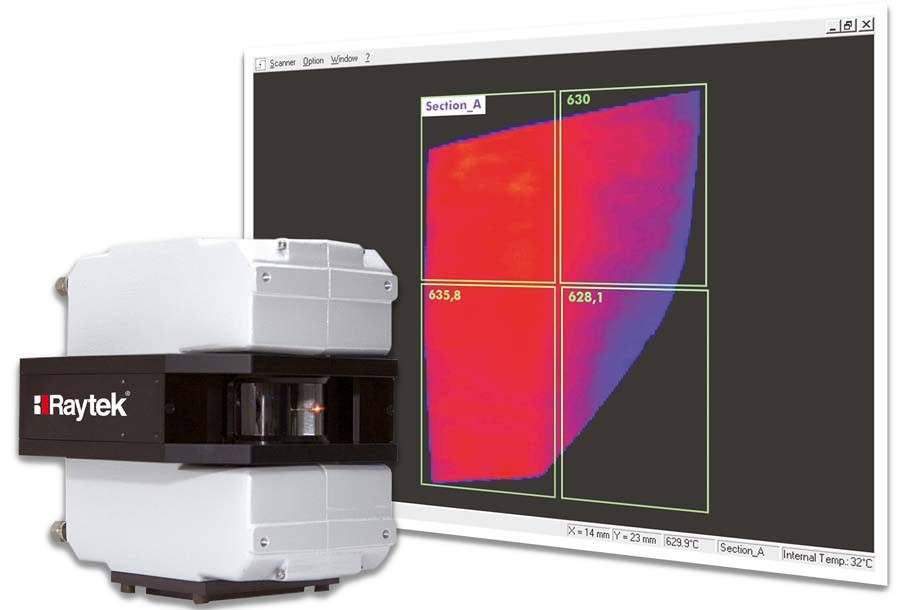

Another measuring device, a Raytek MP150 infrared linescanner, scans each glass pane when it exits the furnace. It generates a thermal image and immediately shows up hot and cold spots. The series comprises various different spectral models, allowing even low-emissivity glass to be monitored. In contrast to thermal cameras, the linescanner needs only a very narrow field of view. It is therefore suitable for manufacturing lines with furnace and quench installed in close [email protected]

- Heat protection range for temperature profiling in paint operations

- Temperature profiler for aluminium vacuum brazing furnaces

- Integrated visible-light camera

- Non-contact monitoring

- Noncontact temperature monitoring in hazardous areas

- Charge and change

- Water cooled sensors

- Noncontact temperature measurement

- Flexible monitoring in high-temperature applications

- Infrared thermometer for steelworks