|

Edward Lowton

Editor |

|

Driving quality improvements in EV battery manufacturing

20 February 2025

There are some exciting developments in automation technology which will improve production of the Lithium-ion batteries electric vehicles rely on, explains Brian Heslop

ENVIRONMENTAL AND economic factors are driving rapid change in mass transportation and energy generation and storage. The race to find more sustainable alternatives is placing increasing pressure on the production of essential components, such as batteries. In electric vehicles, batteries are the largest single cost centre. They are also essential for storing electricity generated from renewable sources (such as wind and solar), which contribute to a more sustainable transport infrastructure.

Ensuring the high quality and consistency of EV batteries is crucial but challenging, due to the complex and sensitive nature of battery components. Variations in the production process can lead to defects, reduced battery life, and safety issues. Automation is key to improving battery quality at every stage.

Forming solutions

Early in the battery manufacturing process, the initial contacting of battery cells with electrical voltage is followed by a critical step known as 'forming'. This term refers to the initial charging and discharging cycles that a battery cell undergoes. During this phase, the cells are placed in forming stations within rack systems and subjected to multiple charge and discharge cycles to ensure their efficacy. Since the forming systems are very large, handling systems with long strokes and high speeds are required.

Drawing on many years of experience with comparable systems for testing hard disks, Festo has developed electric gantries and slides that can achieve the reach and reliability required in battery forming applications. In addition, its ELGT spindle axes are integral to the dynamic and safe loading and unloading of the process chambers. These spindle axes are designed for low contamination environments, with less than 1% copper and zinc content, making them suitable for battery production and small parts handling.

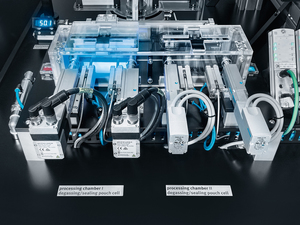

A by-product of the forming process is gas formation within the battery cells. This gas must be carefully extracted without compromising the electrolyte within the welded cells. Pneumatic cylinders facilitate this by moving hollow lances that pierce the cells in a degassing chamber, allowing for the evacuation of the gas. Once the initial electrolyte is drawn in, the system reverses to blow the electrolyte back into the cell, ensuring the removal of any remaining gas. The cells are then resealed, typically through thermal or ultrasonic welding. Process valves like the Festo VZQA are ideal for degassing processes, alongside SPAN-B pressure switches to monitor the pressure within the process chamber. These components are durable, energy-efficient, and flexible, offering a favourable alternative to traditional valves.

Festo's products for battery cell production come with clean room certificates and are suitable for use in dry rooms, further underscoring the company's commitment to providing automation solutions that meet the stringent requirements of the EV battery industry.

Battery testing

HAHN Automation Group is one customer for Festo battery automation solutions. It has developed a battery tester that carries out a complete test of the mobile energy storage units fully automatically. A 3-axis gantry for optical and leak tests, consisting of electric drives from Festo, takes centre stage. The EOLT HAHN Battery is a complete solution for testing battery packs. It is easily scalable, so all relevant test scenarios for 90% of all battery packs available on the market can be implemented on this one end-of-line test system.

The battery pack is contacted with plugs via a standardised coupling that was developed inhouse, while being charged and discharged again. A high-voltage test completes the electrical test routine. To test the leak-tightness of a battery pack, it is filled with helium. A helium sniffing lance for leak testing and a camera for optical testing are attached to EGC 3-axis gantry electric drives from Festo. The axes are actuated by Festo’s EMMT-AS motors and controlled by their CMMT-AS controllers. This means that the drive and control package are perfectly matched.

The battery tester combines several tests and is capable of operating for 24 hours in three shifts. The axis gantry moves and positions the two sensors along all edges of the battery pack to detect any leaks from the battery housing and cooling unit. The integral camera checks that all plates and stickers are fitted correctly, and that the battery pack is processed properly, and detects any mechanical damage. A battery management system then test checks the communication and evaluates the sensors.

Festo's online product finders, intelligent engineering software and engineering tools, mean that HAHN Automation Group designers can find the right products for the development of new machines and systems reliably, quickly and without time-consuming calculations. "As in many previous automation projects, it has been proven that Festo is the right, globally reliable partner in electric and pneumatic automation technology," said Martin Sulzbacher, head of R&D at HAHN Automation Group. "Their easy-to-use design and simulation tools make our work easier."

Fully automated handling

Alongside the development of new components, automation engineers are adapting existing technology to the requirements of battery manufacture. One example is the collaboration between Festo and Siemens to improve the performance of the Multi-Carrier System (MCS). MCS systems are typically used to manage the transition from continuous flow processes, collating variable numbers of carriers and synchronising their motion with stations such as filling heads, insert, cap or seal. These capabilities are highly transferable to volume battery production.

The MCS modular transport system comprising linear motor tracks, customisable carriers, guide systems, conveyor tracks and sophisticated drives and controls. Housed within the track are the electric windings of the motor (stator), which generates a moving magnetic field that drives the motion of the permanent magnet plate(s) housed in the dynamic carriers. There is a direct relationship between the applied current, the magnetic field and the feed force applied to the carrier. The independent carriers are 'handed' from one linear motor track section to another. They can also seamlessly transit onto a traditional conveyor transport system, enabling the linear motor track to be used only where needed. The high dynamics of linear motors offer smooth accelerations, high speeds and precise positioning.

Festo and Siemens have made higher speeds possible by increasing the motor track performance by up to 30%. This was achieved by replacing the fan-driven air cooling with a liquid cooling option, enabling more power to be wrung from the servo motors without affecting life expectancy. This is complemented by an increased feed force, resulting from a greater number of high energy Neodymium magnets (NdFeB) installed on the underside of the carriers. Clamping or holding components on the carrier was another challenge. The team has created custom carriers with onboard solutions for both vacuum and pressure-driven air clamps.

Precision improvements have been achieved by replacing the standard Hall effect encoders with optical encoders, lifting the resolution from ±.01mm to ±25µm. The improved MCS also features Individual RFID carrier identification and data transfer for complete traceability.

Movements of individual carriers on the MCS motor section are entirely flexible. To enable fully optimised battery production, the MCS features kinematic controls that aid rapid reconfiguration and integration with other equipment. The SIMATIC motion control system from Siemens can control other servo drives in the system, such as synchronising external conveyor drives or providing advanced camming functionality. It can handle the carriers individually or as groups, flexibly grouping and regrouping them as required. A powerful toolkit of software tools makes the programming of such a flexible system more straightforward.

Conclusion

Automation can make a real contribution to achieving the increased speed, precision and flexibility that will help deliver more advanced battery solutions at every stage of the manufacturing process. Working with customers and other automation experts is speeding up the development process to deliver the levels of speed, reliability and precision that battery manufacturers require to improve production and drive down costs.

Brian Heslop is business development consultant at Festo

For more information:

Tel: 0800 626 422

- New generation of NAMUR valves

- Bionic robot concepts inspired by elephants, octopuses and the human arm

- Bridging the skills gap

- 25 per cent less power consumption

- A study in smart maintenance

- Latest research projects take inspiration from nature

- Simple approach to motion control

- Six steps to Smarter Factories

- Engineering online

- OPC-Unified Architecture embedded in valve terminals

- No related articles listed