|

Edward Lowton

Editor |

|

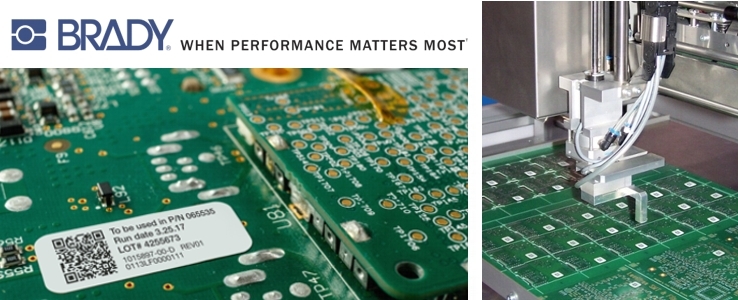

Complete and fully automated traceability labelling

04 February 2019

Discover Brady’s complete and reliable labelling solution for printed circuit boards that can automate traceability and generate smart manufacturing data about your SMD production lines. Meet us at Southern manufacturing & electronics 2019!

Track every printed circuit board

Brady offers a complete traceability solution that can connect every circuit board in production to a Smart Factory set up. With Brady's solution, circuit boards can generate data and send these to a Manufacturing Execution System, to other machines and production cycles, or to the supply chain both up- and downstream.

Discover every component of our complete traceability solution in detail. Download the free brochure!

Reliable labels

Brady's reliable printed circuit board labels are designed for auto-apply and can keep 2D codes and barcodes legible in PCB manufacturing conditions so they can be read by scanners throughout a production process.

- Print and apply labels: polyimide labels designed to stay attached and remain legible in temperatures up to 300°C, or when exposed to typical PCB chemicals and cleaning processes.

- Laser engravable: designed to endure PCB production processes and increase the contrast of laser markings to make them easier to read for scanning systems.

- Masking film: designed to protect PCB's during manufacturing processes, including wave soldering and hot air levelling. The masking film can be removed cleanly.

Test our reliable labels in your environment and see how they perform.

Automate

A fully automated printed circuit board labelling solution can enable traceability and manufacturing data analysis without human interference. Brady can integrate a highly accurate print and apply system in production lines, connect a highly flexible and modular label feeder to existing pick and place machinery or offer a high precision label printer to print labels on-site. Scanners to capture data from 2D coded or barcoded labels can be supplied or integrated in production lines to help generate data for production optimisation.

Visit Brady booth E120 at Southern Manufacturing and Electronics 2019!

BRADY UK

Tel: +44 (0) 1295 228 288

www.brady.co.uk

- Flawlessly finish any cable & component label

- Easily identify electrical panels with just one printer

- Go for Zero Guide: Managing workplace safety risks

- Organise your workplace: tips for effective floor marking

- More efficiency with clear maintenance visuals

- Durably identify pipes in any facility anywhere

- No related articles listed