|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >No need to guess |

ARTICLE

No need to guess

25 January 2013

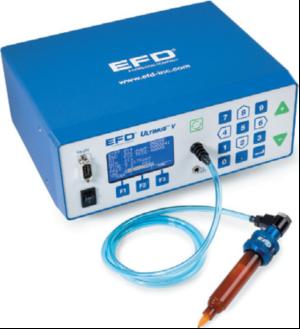

Nordson EFD's precision fluid dispensing workstation, Ultimus V, is said to enable significant productivity increases in assembly processes. It eliminates variability by removing operator guesswork. The amount ap

Nordson EFD's precision fluid

dispensing

workstation,

Ultimus V, is

said to enable

significant

productivity

increases in assembly

processes.

It eliminates variability by removing operator guesswork. The amount applied is determined by a combination of air pressure, dispense time and tip size. To make identical dots or fill cavities with consistent volumes of material, the user adjusts air pressure to achieve the desired flow rate and then sets deposit size with the digital timer.

For fluids that change viscosity, Ultimus V can store and automatically adjust dispensing settings to keep the amount of fluid applied constant.

Stand K31

It eliminates variability by removing operator guesswork. The amount applied is determined by a combination of air pressure, dispense time and tip size. To make identical dots or fill cavities with consistent volumes of material, the user adjusts air pressure to achieve the desired flow rate and then sets deposit size with the digital timer.

For fluids that change viscosity, Ultimus V can store and automatically adjust dispensing settings to keep the amount of fluid applied constant.

Stand K31

MORE FROM THIS COMPANY

- Micro dispensing

- Automated dispensing system with smart vision

- Pump systems for continuous volumetric dispensing

- Improve fluid dispense valve speed and accuracy

- Radial Spinner System Helps Device Maker Eliminate Rework in Critical Lubrication Process

- Fluid dispensers

- Reliability, Consistency and Flexibility in Automated Fluid Dispensing Processes

- Precise operation offered

- Multi-axis dispensing robots

- Fast and accurate

OTHER ARTICLES IN THIS SECTION