|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Efficient gelling |

Efficient gelling

27 November 2013

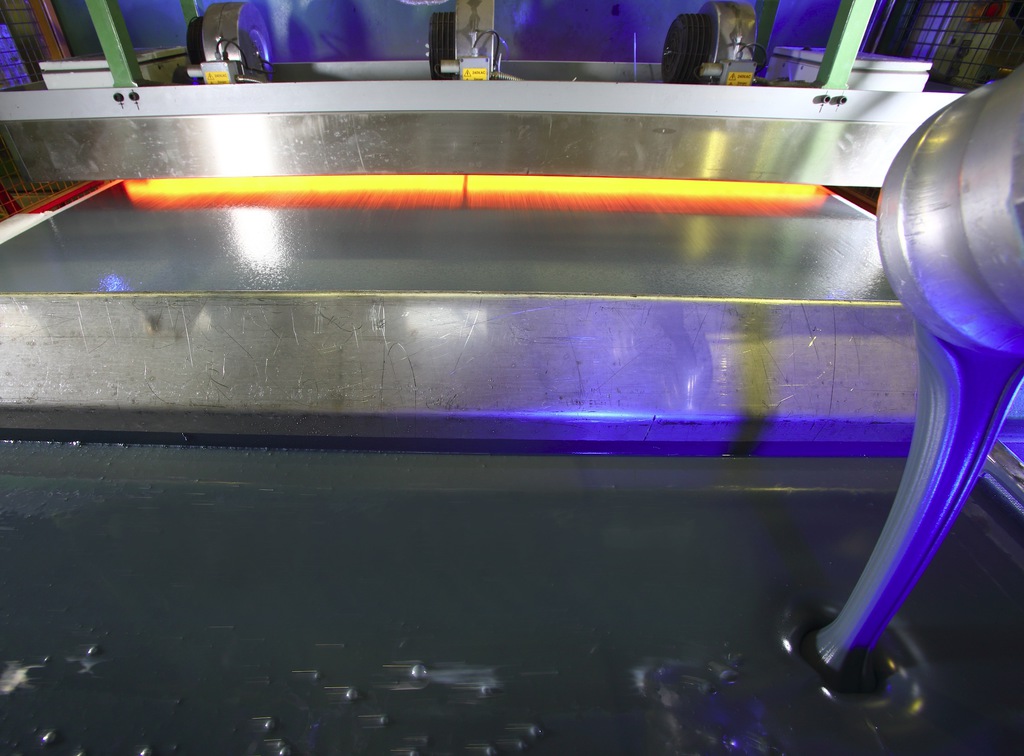

Carbon infrared (CIR) emitters are ensuring efficient PVC gelling during the manufacture of Polyflor's Polysafe slip-resistant range.

PVC gel is applied onto a glass-fibre substrate web. This then passes under a heated chrome drum to ensure a smooth surface finish prior to clear aluminium oxide particles being deposited in the PVC surface to achieve slip-resistant properties. Polyflor used to find that the gel was sometimes still liquid, which led to it running off the web.

Heraeus conducted trials using a CIR emitter test module. These proved so successful that a 72kW CIR medium wave cassette was installed on the process line to heat the PVC in a gel drum. It is controlled by its own optical pyrometer to ensure that the gel attains a temperature of 60°C. This is achieved using only three of the six emitters in the cassette. The installation has prevented un-gelled PVC running off the edges of the substrate, saving product and eliminating process and maintenance problems.

- On a mission

- Infrared systems speed up production line

- Fast response infrared heating system

- Soluva UVC helps provide Covid protection in Cambridge factory

- Infra-red emitters in browning role

- Carbon infrared heating system

- IR heating in quality role

- Gas catalytic infrared oven installed for customer trials

- IR drying systems cuts cost on coating line

- Print drying is just the ticket