|

Edward Lowton

Editor |

|

Fast reponse infrared heaters

23 March 2018

Four fast response, medium wave infrared (IR) heating modules from Heraeus Noblelight are helping Tarkett reduce the risk of damage to flooring products manufactured at its Maidstone factory in the event of a power cut-out or unexpected stoppage of the production line.

Tarkett provides integrated flooring solutions to architects, facility professionals, contractors, distributors, installers and end users.

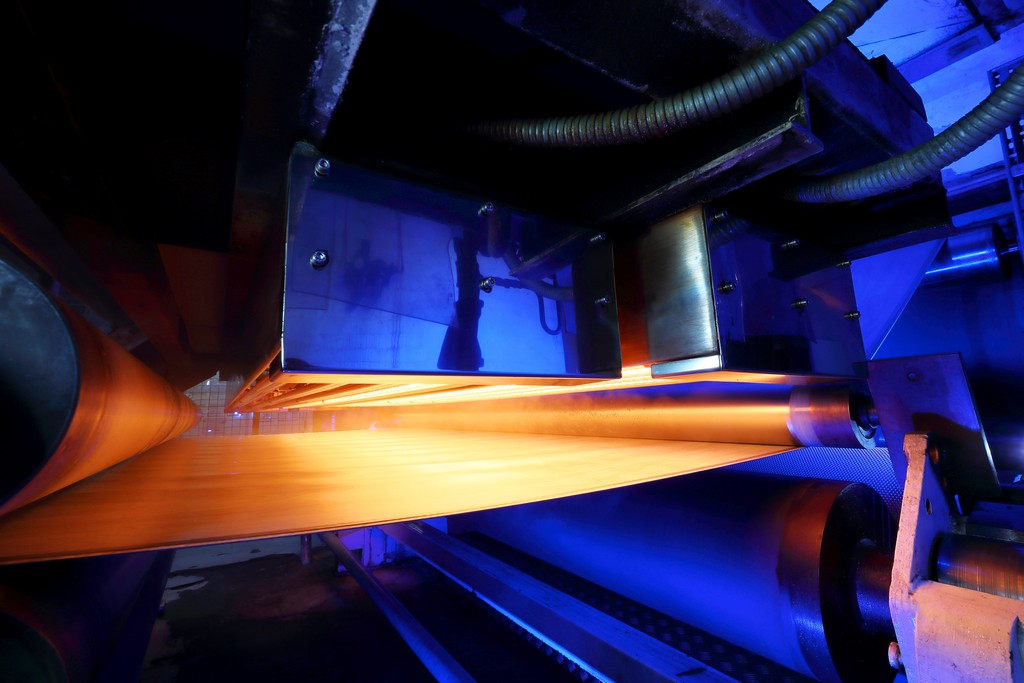

The basic flooring production process consists of building up thicknesses of pvc paste on a pvc backing layer in 2m wide sections. This basic product then needs to be embossed and this requires the pvc layer to be softened before the web enters the embossing machine. Previously, this flash heat had been applied by means of standard medium wave infrared emitters. However, in the event of line stoppage, these heaters had to be physically retracted and this relatively slow process meant that product in the heating zone could be damaged or spoiled.

To mitigate this danger, Tarkett replaced its IR heaters with four 22.5kW, fast response IR heaters from Heraeus. These can be switched on and off in a matter of seconds, so there is now no need for the module assembly to be retracted.

As John Williams, operations manager at Tarkett, explains, “The new heaters have proved eminently successful as we can now switch off the heaters virtually instantaneously, minimising the risk of any damage to the product. Retrofitting the new IR units has also been very simple, as they use the same power supply and the same control system as the previous IR heaters, so there was minimum production disruption.”

- On a mission

- Gas catalytic infrared oven installed for customer trials

- Soluva UVC helps provide Covid protection in Cambridge factory

- Infrared and flash lamp heating

- Speeds up heating

- Chocolate moulds get pre-heat treat

- Queen’s Award For Enterprise winner

- Heraeus infra-red ensures polymer-polymer bonding in roofing manufacture

- Warming role at chocolate maker

- Carbon infrared heating system