|

Edward Lowton

Editor |

|

Repels welding spatter

17 April 2014

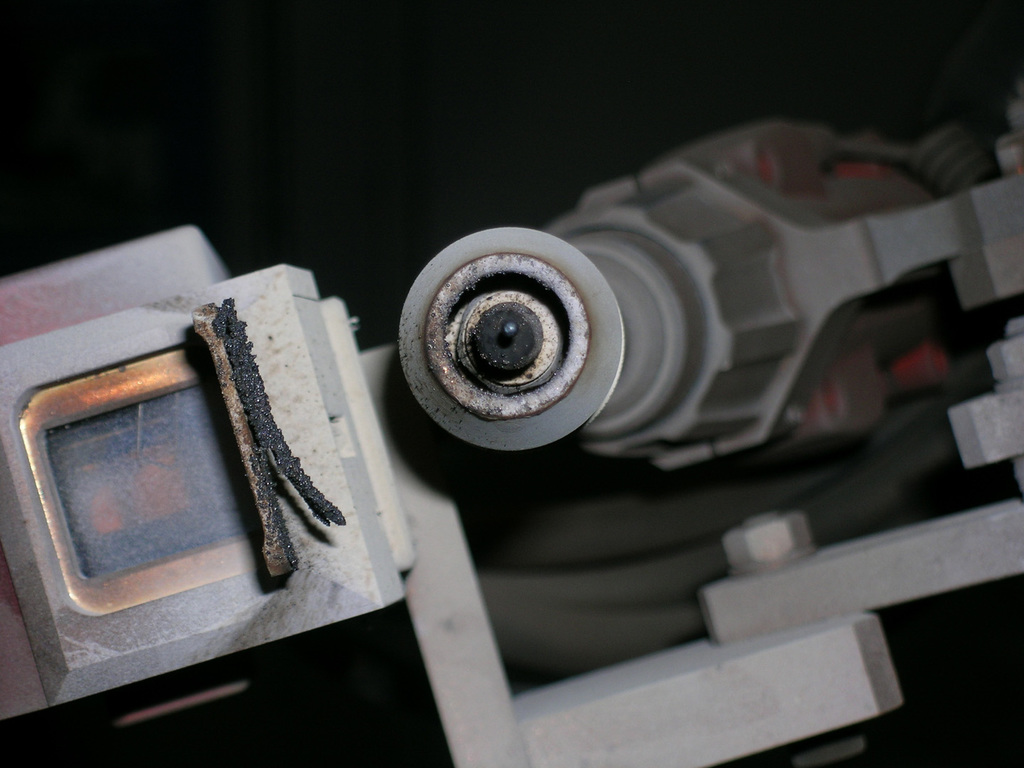

Henkel’s Aerodag Ceramishield, now known as Loctite SF 7900 Ceramic Shield, is a protective coating formulated to actively repel welding spatter.

This dry film is easy to apply, dries in seconds and adheres well to contact tips, shrouds, welding nozzles and jigs. It is sprayed directly onto degreased surfaces from an aerosol can, creating a ceramic coating that prevents adhesion of welding spatter for up to 8h without the need for re-application.

The company says users of Loctite SF (silicone-free) 7900 Ceramic Shield report productivity gains of up to 10% and a reduction in the cost of consumables by up to 70%. After the shift, a gentle tap on the welding torch removes minor spatter build up and the equipment is then ready for a top-up coat. There’s no need for expensive and environmental hazardous chemicals to release the spatter.

Another advantage of Loctite SF 7900 Ceramic Shield is that it provides both physical and thermal protection, both of which increase the service life of welding equipment. The quality of the weld seam is enhanced as the shroud remains spatter-free and the gas flow is not interrupted.

Laser and plasma cutting nozzles are particularly sensitive to spatter; an application of Loctite SF 7900 Ceramic Shield ensures the machining process is unimpaired. The coating also projects jigs, fixtures and fittings against spatter for up to a week and can be used on power cables, sensors and other metal components for the same purpose.

- Repair system for pipes

- Thin film conversion coatings

- Adhesives, sealants and coatings

- Instant adhesives: Latest advances

- Cost-effective, anti-spatter

- HEALTH AND SAFETY ENGINEERING ADHESIVES

- eShop for adhesives, sealants and coatings

- Henkel introduces new handheld adhesives dispensers

- Quick to achieve a lasting bond

- Composite repair minimises processing downtime