|

Edward Lowton

Editor |

|

Electric valve control

21 May 2014

Rotork CVA electric control valve actuation technology is helping Coca-Cola Enterprises (CCE) in its bid to increase efficiency and reduce energy costs at its Wakefield production plant.

An important part of the plan involves saving the on-going cost of providing and maintaining an instrument air supply for traditional pneumatic control valve actuation. This is being implemented by the introduction of the Rotork CVA control valve actuator to perform modulating and failsafe valve duties.

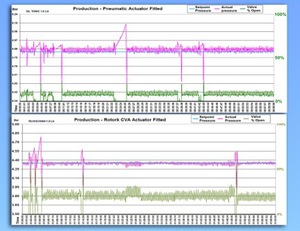

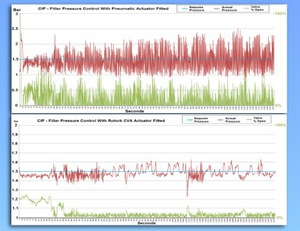

A recent example is on the production line where the adoption of Rotork CVA technology for a demanding valve duty has considerably reduced the cost of energy consumption when compared with traditional pneumatic actuation with no loss of performance.

- No related articles listed