|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Boilers and burners | >Fast acting damper drives |

Fast acting damper drives

20 March 2014

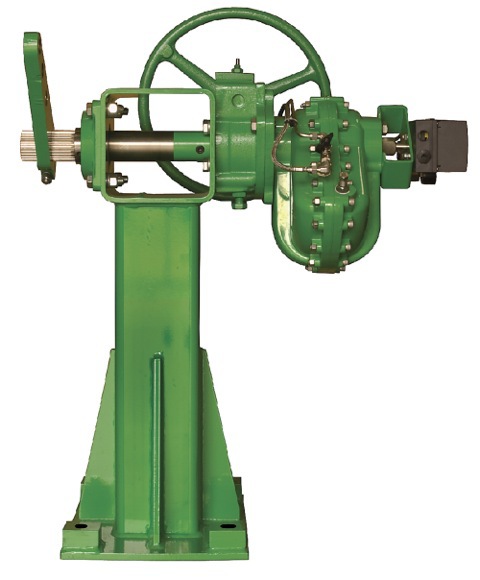

With environmental legislation driving ever stricter efficiency and control of emissions from industrial boilers, furnaces and other power plant processes, replacing obsolete equipment with fast acting Rotork Type K damper drives helps enable improved burner management and cleaner performance.

With environmental legislation driving ever stricter efficiency and control of emissions from industrial boilers, furnaces and other power plant processes, replacing obsolete equipment with fast acting Rotork Type K damper drives helps enable improved burner management and cleaner performance.

The Type K offers a swift ‘drop-in-place’ retrofit solution that precisely fits the application without any field engineering or fabrication. Existing connection rods and linkages can be used without modification; commissioning is quickly and simply completed.

- Rotork appoints new CEO

- Valve actuators selected for critical coal seam gas application

- Change of transducer boosts die casting performance and cuts costs

- Explosion-proof

- For quarter-turn applications

- Intelligent part-turn valve actuator

- Automation contract completed

- Handy in hot water

- Emergency shut-off solution protects pipelines on bridge

- Wireless valve monitoring