|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Software | >Recipe for success |

Recipe for success

24 November 2014

The latest release of FactoryTalk Batch software from Rockwell Automation eases the process of modifying and creating new recipes by managing the approval process for changes and automatically tracking the genealogy of recipes.

New security-authority binding features also help manufacturers protect their intellectual property.

"FactoryTalk Batch software removes risks associated with manually managing recipe changes," John Parraga, FactoryTalk Batch product manager, said.

"The upgraded software, which tightly integrates with the PlantPAx process automation system from Rockwell Automation, provides solutions ranging from small, basic sequencing to large, complex batch and sequencing applications. It simplifies the management of recipes throughout their life cycle and provides standard reports containing vital actionable information."

Administrators can use the software to assign specific people or roles to approve recipes before they advance to the production line. This structured approach provides approval traceability and allows quality control managers to easily manage recipes.

With new version-control capabilities, FactoryTalk Batch v12.0 software preserves and locks recipes from changes.

- New capabilities

- Actionable manufacturing insight

- Rockwell Automation to Acquire MagneMotion

- Photoelectric sensor for demanding applications

- Shaping the industrial landscape

- Light curtain system enhances safety and productivity

- Motion over ethernet

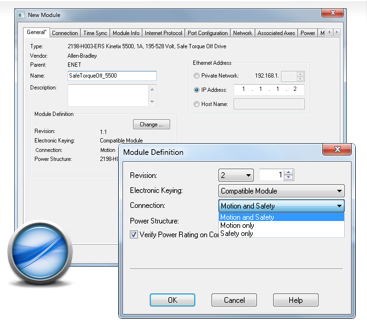

- Functional safety

- The business value of Industry 4.0

- Challenging public perception of robotics