|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Bespoke disentangling |

Bespoke disentangling

30 November 2015

The latest MAFU Automation disentangling and feeding equipment from R. A. Rodriguez allows the company to add greater depth to its automation business.

MAFU systems allow users to sort, feed and accurately place non-sensitive parts regardless of size, material or geometry.

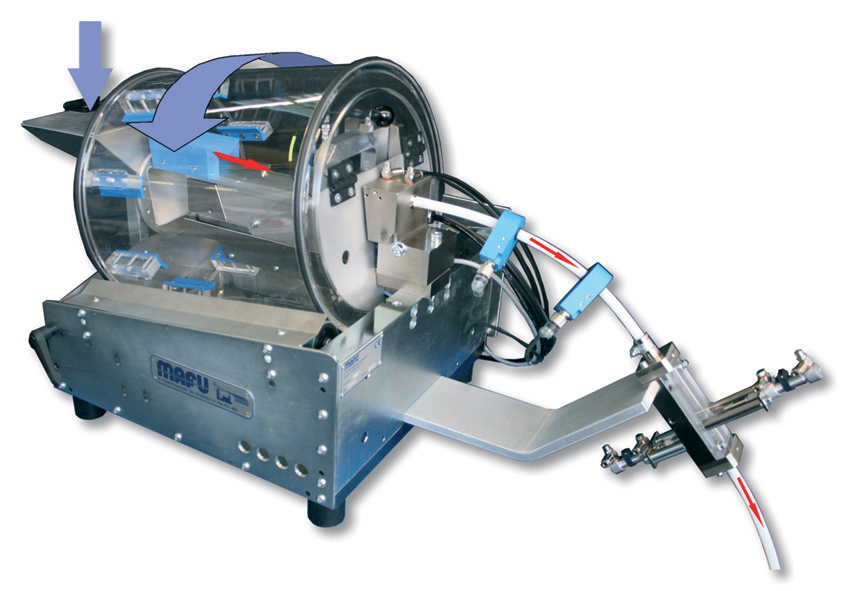

At the heart of the MAFU disentangling is its drum system. Bulk goods such as springs, pins and bent-wire parts are fed into the drum via a funnel and its rotation allows parts to be gently disentangled and released to the outlet. A variety of hopper systems are available for bulk feeding and there is a wide choice of different drum designs and sizes to suit the application; these include antistatic, sieve and acrylic options.

After disentangling, the individual parts are released onto a choice of patented separation systems according to the nature of the product and how it is to be further processed. Examples are output via tube for springs, pins and sleeves; on-rail threading for circlips or rings and on-rail hanging for screws, rivets and nails.

- Mission critical

- Robot returns

- Easy automation of sanding tasks

- Robot with plug-and-play productivity

- Mobile robot designed for production logistics

- Robot picked for tea handling role

- Turnkey solutions

- RARUK Automation delivers WiFi-free AMR communication

- Grippers added to robot package

- Robot routine grabs attention