|

Edward Lowton

Editor |

|

| Home> | Premises management/maintenance | >Cleaning equipment | >Flexible friend |

Flexible friend

12 December 2015

A centralised vacuum cleaning system from Quirepace is proving an efficient solution for a credit/store card manufacturer.

Cards each have an area on them where the chip is housed and it is this recess in the plastic card which has to be milled generating plastic waste.

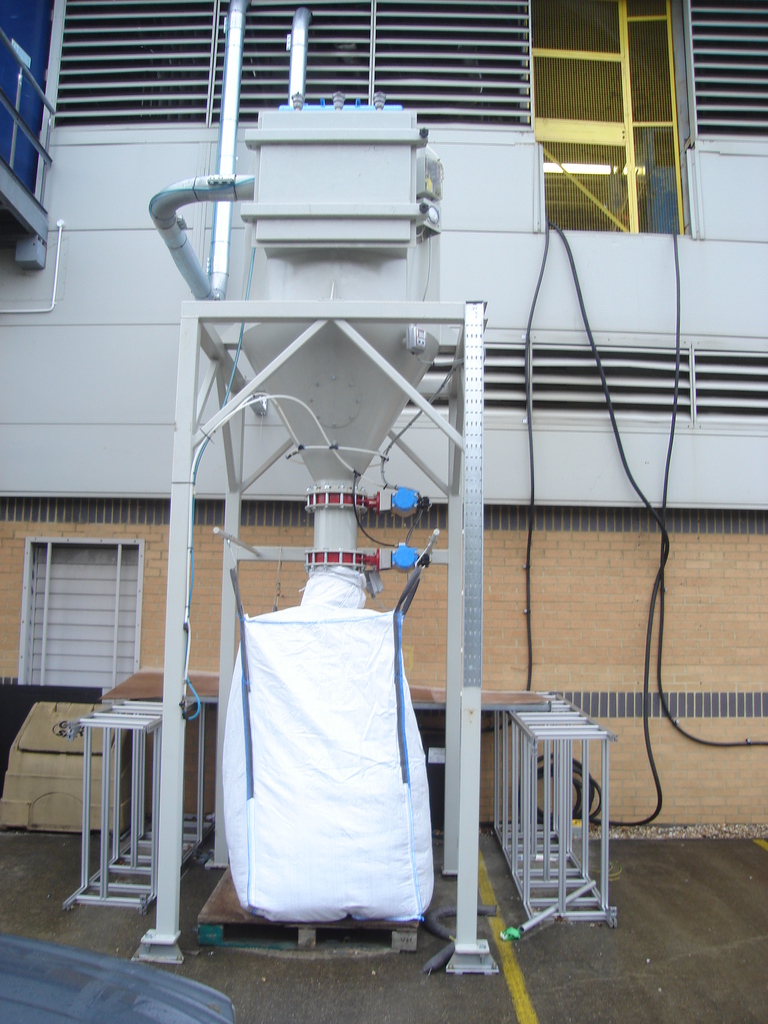

Quirepace designed and installed a vacuum system which allows up to seven specialist milling machines to be operational simultaneously extracting dust at source and conveying it to a reverse jet cartridge filter separator. There is continuous discharge into the clients FIBCs, with motive air being generated by two centrifugal exhausters each powered by a 22kW motor.

The client previously had a number of static vacuum cleaning machines within the process area, which generated additional heat. This heat generation meant the client had to provide air conditioning to reduce the factory temperature level which was expensive. An additional bonus from the centralised system is that the extracted materials are automatically bagged into FIBC’s; there is no need to empty the bins on the vacuum machines and the noise level within the production facility has been reduced.

The system has been extended to a card shredding machine. The shredded material is pneumatically conveyed to the filter separator and onward to the FIBC below the unit’s outlet for off-site disposal.