|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Assembly equipment lifts automotive production |

| Home> | Handling and Storing | >Safer manual handling | >Assembly equipment lifts automotive production |

Assembly equipment lifts automotive production

18 October 2016

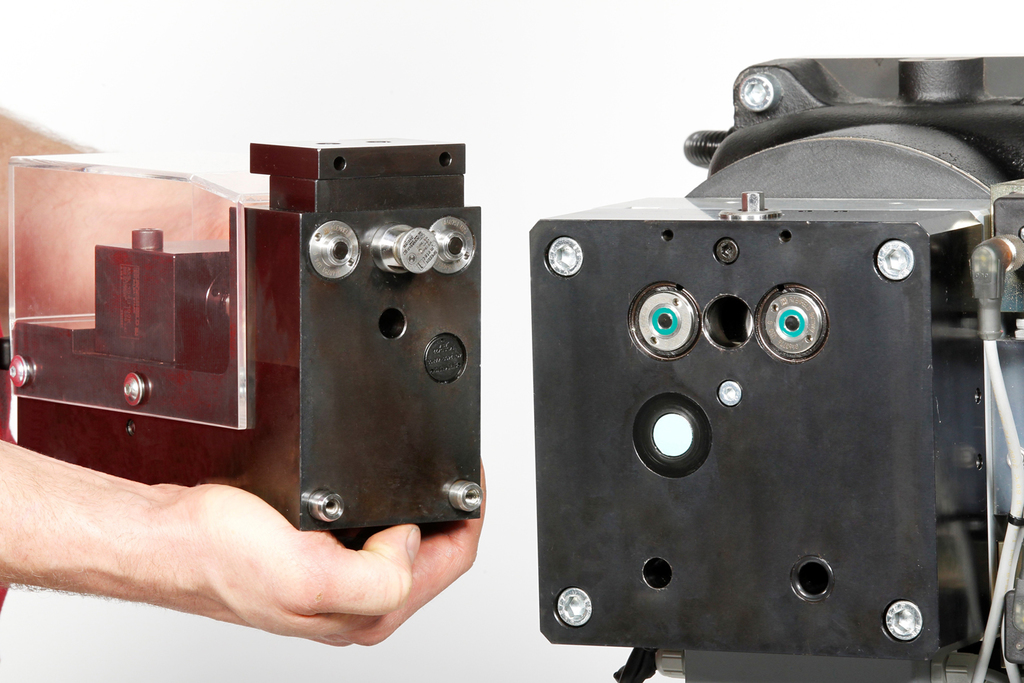

The Roemheld Modulog assembly and handling system is designed to bring safe, ergonomic and secure hand assembly to automotive workstations and green button cells.

Various linear and rotary modules, some with integrated media ducts, are easily operated via either a small command module or foot or hand switches. They enable the operator to carry out assembly work ergonomically and fatigue-free at the different positions of the component.

The Roemheld Modulog system consists of a variety of combinable components for lifting, rotating, panning, tilting and fixing of mechanical components. The range includes lifting columns and pressing devices. There are also modules that enable information from RFID chips to be read on workpieces and components, as well as modules that communicate with each other and monitor themselves.

The adaptability of the Modulog system is suitable for a variety of applications including use in highly flexible, semi-automation of manual workstations.