|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Fasteners, springs and adhesives | >Custom Stampings and customer standards from Lee Spring |

Custom Stampings and customer standards from Lee Spring

19 September 2017

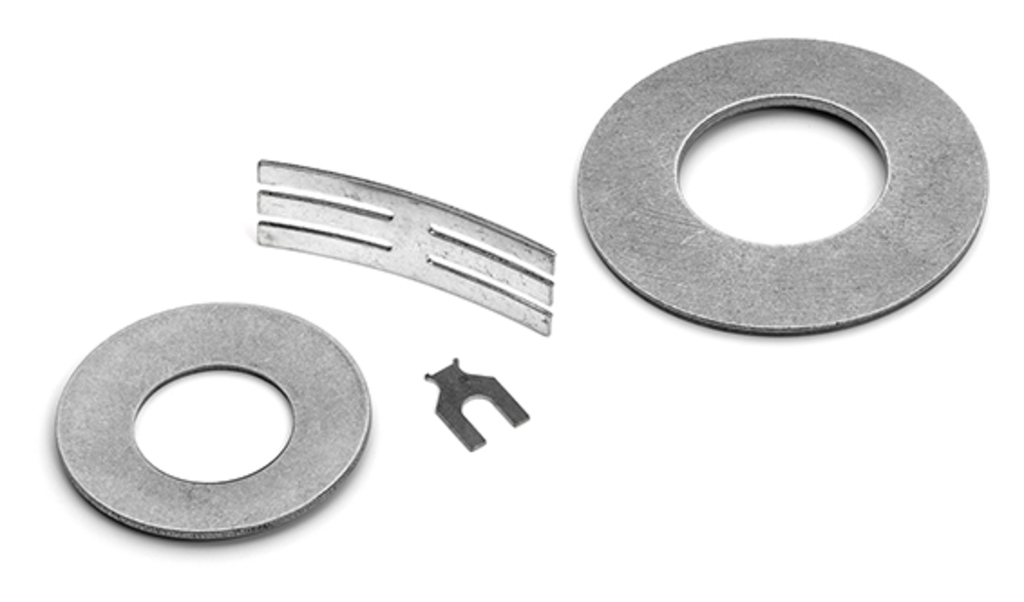

Custom stampings are often at the heart of equipment – making connections, retaining components, operating elements within an OEM device. Each is normally required to fit a specific (custom) space or deliver a special operation and this is where Lee Spring can offer a high degree of expertise.

Based on their long experience of producing standard and custom products, Lee Spring work from customer drawings with CAD (SolidWorks) to develop short run and prototype stampings and assemblies through a complete Process Validation Procedure including 1st Articles and PPAP’s.

Typical products include latches, retainers, bridging parts, special conductors, hinge components, fasteners and connector clips. These are especially found in applications for telecom, electrical, electronic, aerospace, automotive, medical and white goods manufacture.

Materials include low and high carbon steels, chrome vanadium, beryllium copper, Elgiloy, Hastelloy, Inconel, phosphor bronze and brass, as well as many types of stainless steel.

Lee Spring offer a catalogue range of 25,000+ ex-stock same day despatch springs and related products, and custom production service for springs, wire forms and fourslide parts.

Further information on Lee Spring products can be found on their website - www.leespring.co.uk or follow them on twitter - https://twitter.com/leespringuk.

- Lee Spring announces expansion to Lite Pressure

- New products on show

- New Lee Spring products at the Northern Manufacturing Show 2015

- Plastic composite compression springs – a complete package

- Catalogue of springs

- Spring range expanded

- Metric springs

- A LeeP in spring technology

- Extended spring range

- Lee Spring's 23 Series Catalogue is available now