|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Automation | >Robotically controlled finishing station |

| Home> | Production Engineering | >Automation | >Robotically controlled finishing station |

Robotically controlled finishing station

17 October 2017

Guyson International has introduced a robotically controlled finishing station and powder recovery system – the Guyson PRS .

Known for its design and manufacture of blast finishing, spray wash and ultrasonic cleaning equipment, Guyson is now carving a niche in the 3D and additive manufacturing (AM) industry, producing blast cabinets to facilitate production of 3D components in the aerospace, medical implant and automotive sectors.

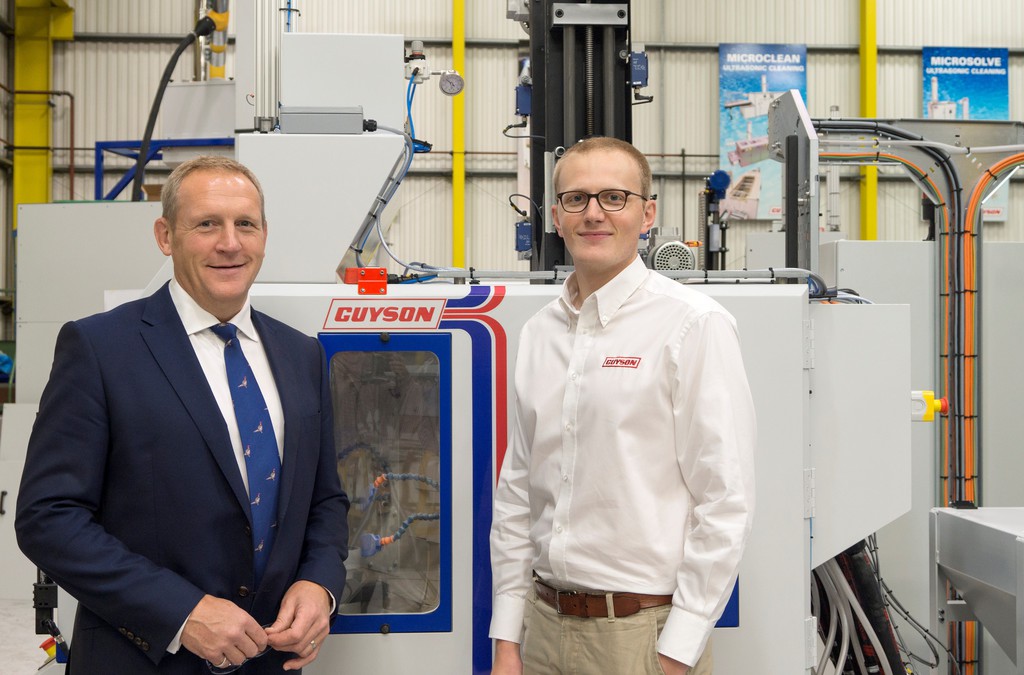

Mark Viner, managing director of the Guyson Blast & Wash Division, is leading the 10-strong team into the expanding market of additive manufacturing, which he says, is already responsible for 20% of the company’s machine sales.

“The AM market is growing rapidly and we are growing with it. It’s a form of manufacturing that has been developing in the background for the last 20 years but over the last five, we have seen an acceleration in demand for products which facilitate fast, efficient and cost effective additive manufacture,” he explains.

“We offer a range of solutions from entry and mid-level manual finishing stations through to the Guyson PRS which uses robotic blasting methodology to reveal components and reclaim the valuable and re-usable powder. While this time and cost saving process is invaluable in any additive manufacturing business, it’s particularly in demand in the aerospace, medical implant and automotive industries where companies want automation to manage volume and ensure product consistency.”

Jimmy Thomson, business development manager and fourth generation of the Guyson-founding Thomson family, adds: “British manufacturers have always been adaptable and our future relies on diversification. Growth in the AM industry complements our core, established areas of expertise and we are relishing the challenge of applying eight decades of Guyson manufacturing expertise to this evolving market which is changing the face of production across the globe.”