|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Slip, trip and fall prevention | >High level support |

High level support

01 August 2018

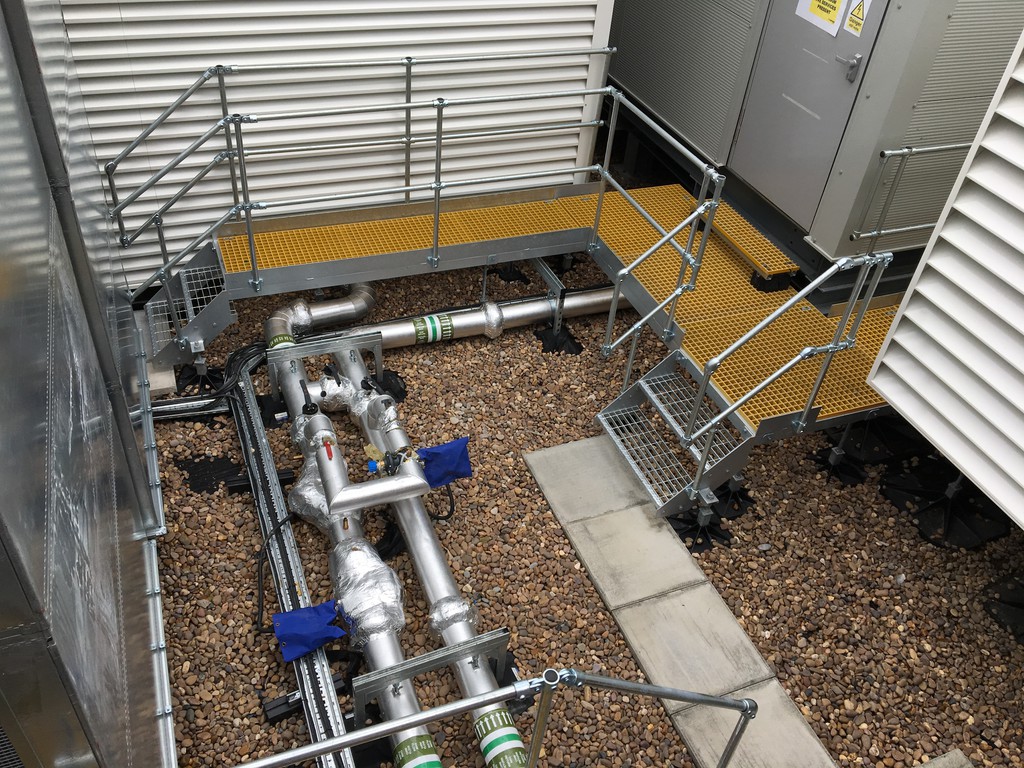

Big Foot Systems has supplied a complete solution for rooftop plant support on a commercial office building in central London. The split-level project used a range of non-penetrative frames from Big Foot Systems including Custom Safe Access systems, Bespoke Frames, Custom HD Frames, HD Cubes and Custom HD Supports to provide safe access and support air handling units, chillers and high level pipes.

At the start of the project, the Big Foot technical team held several meetings with the contractors Kier Construction to design a solution for this large and multifaceted project. After an initial consultation it was decided to increase the complexity of the systems being used in order to combine many different supports and access ways, so that the project fully met the needs of the customer. After detailed surveys were completed, drawings and 3D assemblies were provided to the customer along with technical calculations to back these up.

“The size and complexity of this project proved to be a real challenge,” explains Nathan Wood, site engineer at Big Foot Systems. “To design a system with over 500 different parts to fit in an unusual space meant we had to think outside our normal design practices to provide a solution that worked well. Also, due to the time constraints, it was critical to provide these quickly and efficiently.”

On the project the roof was split into two levels, level 9 and level 11. The supports for level 9 included: a custom HD frame supporting an air handling unit (AHU) weighing over 7800kg, custom access to service the AHU, and integrated access and pipe support for seven large volume water pipes at 4m above the roof level. Meanwhile, supports for level 11 included: HD Cubes supporting four chillers weighing 5,700kg each, two bespoke frames supporting air handling units weighing 6,500kg each, a custom HD support with integrated access for a 15,750kg generator and over 100m² of custom safe access. The deliveries of the frames were staggered over six months to allow all the different services to be coordinated with Big Foot Systems, with full assistance offered to aid the install by the site team.

Big Foot Systems can design and manufacture complete one-off solutions that can be designed and fabricated specifically for the project requirements. This is useful when the standard offer may not be suitable in meeting specific application requirements placed on today’s roofs. Limiting factors such as weak roof construction, space constraints, existing upstands/services obstruction and stacked/sectioned unit arrangements are typical scenarios that contribute to the need of detailing an appropriate custom support solution. Big Foot’s technical team then undertake a site survey and design custom systems, tailored specifically to meet individual design parameters.

The Big Foot Safe Access range is designed to allow a secure route for service engineers and other trades to gain access to plant and for managing the flow of other personnel, offering secure and easy access to roof-top services. HD Custom Frames are project specific non-penetrative support frames for large, heavy, irregular shaped or unevenly loaded plant whilst LD Custom Frames are ideal for supporting air conditioning and ventilation equipment.

The adjustable HD Cube provides a complete, efficient and robust solution for supporting heavier services and is an alternative to heavy, complex frameworks. Offering fast assembly and available in multiple configurations, HD Cube offers excellent load distribution making it suitable for large packaged plant rooms, chillers and large air handling units.

Offering specifiers a comprehensive range of freestanding systems, Big Foot’s products are designed and manufactured by the company for a wide variety of applications, including HVAC, solar units and safe access equipment. The product portfolio provides complete, simple, safe and secure non-penetrative, prefabricated roof support systems negating a need for time consuming and costly penetrations through the roof.