|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Software | >Scheduler uses AI-assisted autonomous machine learning |

Scheduler uses AI-assisted autonomous machine learning

09 April 2019

MangoGem, a provider of intelligent software solutions for challenging enterprise problems, has launched Version 2.5 of its Oritames Advanced Planning and Scheduling system.

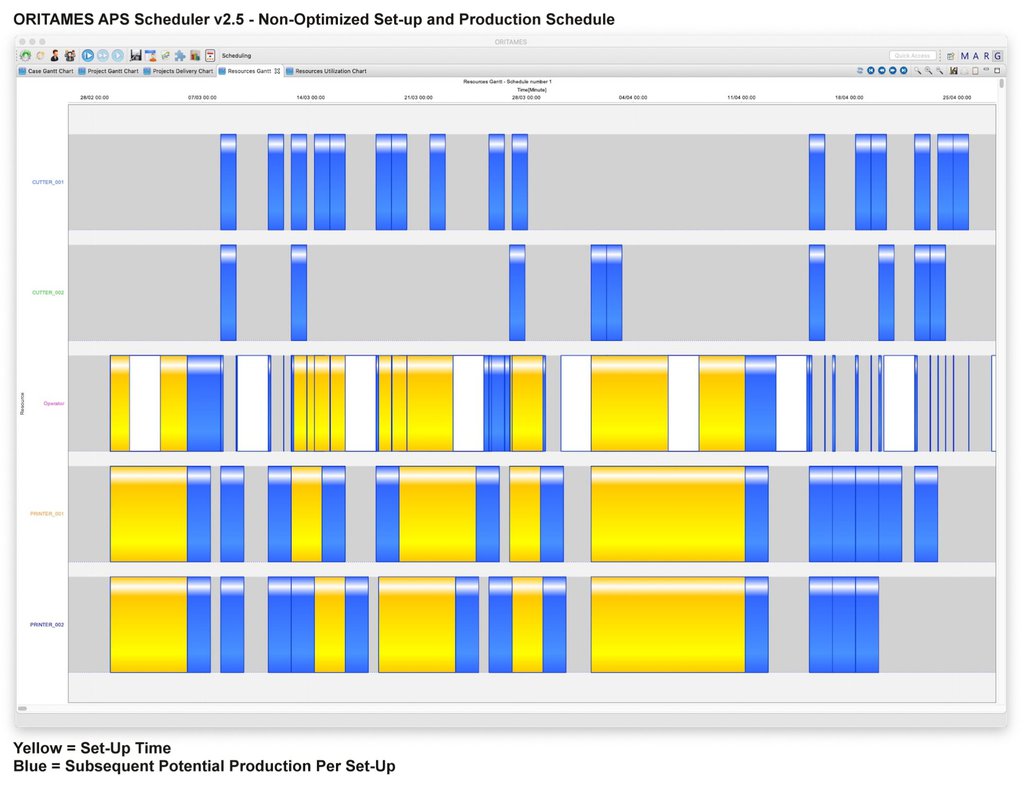

The Oritames APS Scheduler v2.5 incorporates autonomous Artificial Intelligence (AI) capabilities for improved planning and schedule optimisation, as well as improved modelling of sequence dependent setups, batching and time constraints, making it suitable for large, real-life problems taking into account the complex constraints of real cases.

Ben Rodriguez, chief technology officer of MangoGem, explains: “The Oritames APS Scheduler v2.5 uses AI-assisted autonomous machine learning to explore optimisation scenarios better than traditional approaches, combining the best of machine computing power and human know-how to facilitate better planning and scheduling."

With solver heuristics notoriously difficult to fine tune, the Oritames APS Scheduler v2.5 discovers which settings work best, checks validity and detects trends in data to improve ramp-up and adoption. It can also discover the most promising improvement scenarios and propose them as potential solutions to human planners. It combines several AI-assisted machine learning meta-heuristics including Genetic Algorithms (GA), Taboo Search (TS), Simulated Annealing (SA), Swarm Intelligence (SI) amongst others. The use of AI-assisted autonomous machine learning also eases the integration and reduces the cost of implementation of the Oritames APS Scheduler v2.5 within overall supply chain management (SCM) strategies by making modelling easier, improving data quality and decreasing dependency on human expertise.

Oritames APS Scheduler v2.5 is a multi-resource scheduler capable of handling multiple instances of equipment, people, consumables, tools, locations etc. It can also combine several resources and any activity can have multiple modes to closely model reality. It also supports the selection of multiple objectives and multiple criteria, such as makespan, deadline satisfaction, cost reduction, Just-in-Time, throughput, resource utilisation or consumables usage, combining several key performance indicators (KPIs), producing optimal schedules and analysing objective trade-offs and 'what if' scenarios without effort.

Oritames APS Scheduler v2.5 is platform-agnostic, running on MS Windows, Mac OS and a variety of UNIX and Linux platforms. It can be used as a standalone application or it can be easily integrated with other Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) tools. It can be used offline, online and even in real-time and its parallel, multi-threaded solvers ensure that it creates optimal scheduling solutions extremely fast.

It is suitable for a wide variety of industries, organisations and applications, including discrete manufacturing (metal, glass, furniture, electronics, quarries, food processing etc.), construction and infrastructure projects, logistics and transportation, equipment and property maintenance, engineering projects and service organisations (schools, hospitals etc.). Fexible modelling capabilities and business rules scripting extensions make it easily adaptable to many applications without the need for heavy customised programming.

“The AI-assisted disruptive technology delivered in Oritames APS Scheduler v2.5 is capable of solving many of the operational performance challenges of Industry 4.0,” concludes Rodriguez. “It uses AI-assisted autonomous machine learning techniques with multiple solvers and heuristics and, depending on an analysis of the case at hand, will apply many methods to find the one that produces the best results.”

- No related articles listed