|

Edward Lowton

Editor |

|

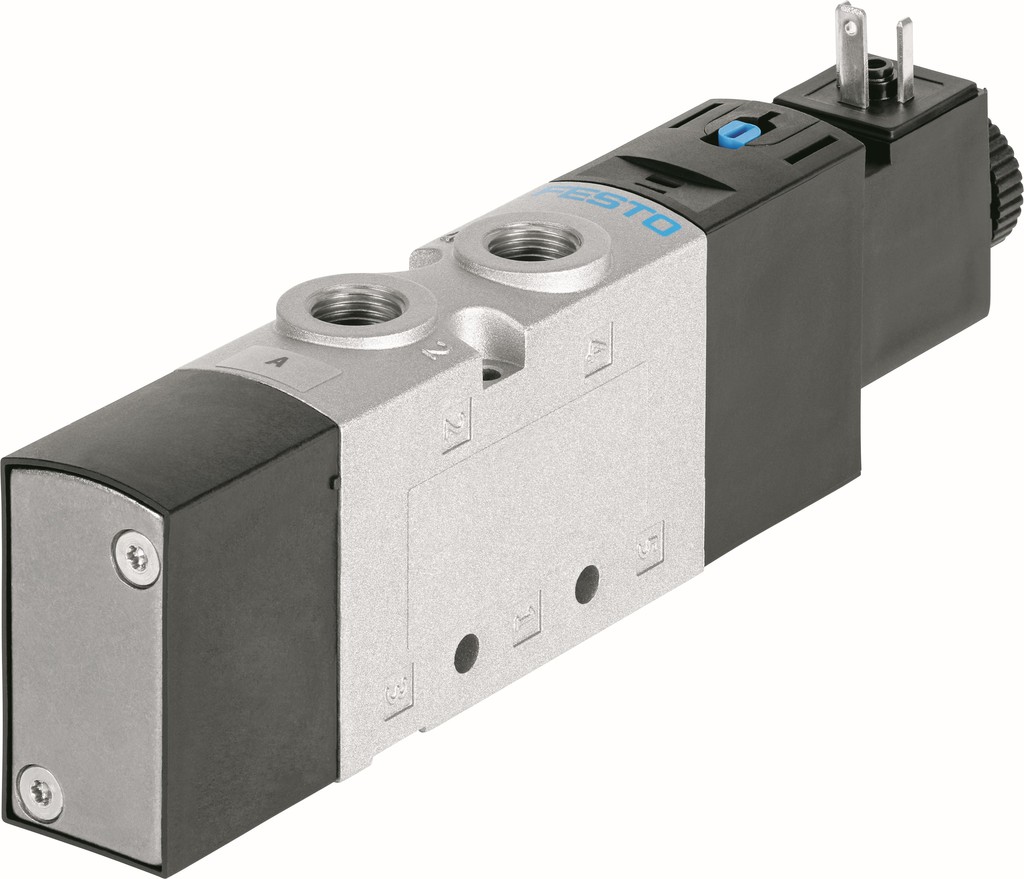

New poppet valves for standard and hazardous applications

12 June 2018

Automation specialist Festo has extended its Blue Star core pneumatics range with the addition within its VUVS valves range of a new poppet operated valve.

Available in standard or ATEX-certified versions, the VUVS poppet valve offers OEMs, machine builders and specifiers greater choice of high quality pneumatic components at a competitive price.

The simple construction of poppet valves makes them well-suited to applications where contaminated air may be present. In addition, they do not require lubrication, which is an advantage in terms of eliminating any potential problems with chemical compatibility due to lubricated compressed air.

Festo’s VUVS poppet valves are said to offer up to 58% faster switching times than their spool valve equivalents, making them suitable for applications where responsiveness is a key consideration. Festo says there is also less friction during operation, which means the poppet valve delivers a more consistent performance and repeatable switching times.

The VUVS poppet valve is available in three port sizes: ⅛, ¼ or ⅜in. A double 3/2 function, providing two valves to be combined in a single body, offers significant savings where space is at a premium. ATEX versions, certified for use in Zone 2 explosive atmospheres, complete the new additions.

There are more than 2300 Blue Star core products available for pneumatics, including: cylinders, valves, regulators, sensors and accessories, as well as products that meet the specific requirements of process automation. These include solenoid, NAMUR and angle seat valves, positioners, sensor boxes, ball valves and ball valve actuator units, products for air preparation and accessories.

With such a wide choice available as standard, Festo also offers users and specifiers free guidance on how to select the best Blue Star product for an application. This information is available free online in a number of formats, from a series of short videos to top tips. For those seeking more in-depth information on when to select poppet or spool valves there is also a white paper giving a technical comparison of available solenoid valves, sealing technologies and their relative advantages.

- Tips on maintaining network security

- Ground-breaking piezo proportional flow control valve

- Whitepaper outlines how software can accelerate design of automation systems

- Swimming robot inspired by nature

- A study in smart maintenance

- Driving quality improvements in EV battery manufacturing

- OPC-Unified Architecture embedded in valve terminals

- Pneumatic safety

- Suitable for food and splash zones

- Six steps to Smarter Factories

- No related articles listed