|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Cables & Connectors | >Sealing elements for maximised cable packing density |

| Home> | Production Engineering | >Cables, connectors and energy chains | >Sealing elements for maximised cable packing density |

Sealing elements for maximised cable packing density

06 April 2020

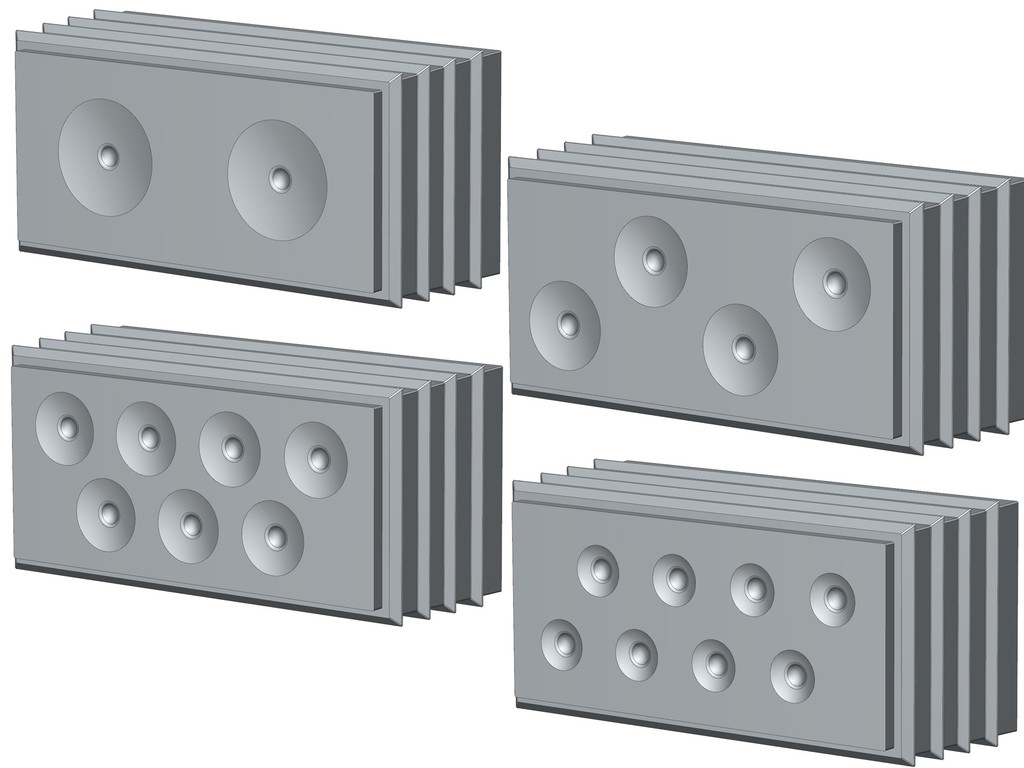

By developing the KDS-DES sealing elements for unassembled cables, CONTA-CLIP has transferred the simple cable entry principle of its KES system to its KDS cable feedthrough system.

To insert a cable, the membrane of this newest sealing element is first pierced at the marked centre, whereupon the cable can be pushed through the selected channel. The design, based on the proven KES system, ensures reliable sealing to IP64.

The KDS-DES variants currently available accommodate up to eight cables, depending on cable diameter. This can range from 4.5 to 10.5mm.

Despite the high packing density, KDS-DES sealing elements are compatible with almost all KDS solutions. Like those, they are pressed into the frame openings for installation from the inside. Their conical shape allows easy insertion and reliable sealing of gaps.

- Through-wall plug connection

- Fuse disconnect terminal

- New brush sealing cable entries for effective protection against dust and drafts

- New range of sealing plugs

- Screwless cable entry system

- Feed-through terminals

- Adels-Contact and CONTA-CLIP sign strategic partnership

- Easy customisation of cabling ducts

- Large cross sections

- Added printing height