|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Power transmission | >Fail-safe short shaft couplings introduced by KTR |

Fail-safe short shaft couplings introduced by KTR

27 September 2021

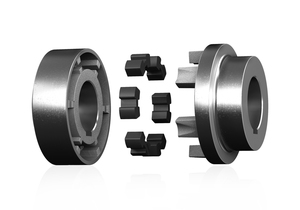

ROFLEX FAILSAFE is a service-friendly short shaft coupling, developed by KTR in accordance with DIN 740.

In addition to power transmission, the torsionally flexible coupling compensates for misalignments and dampens torsional vibrations. The ROFLEX is available in two designs and currently in seven sizes for torques from 65 to 790Nm. A further five sizes will be added by the middle of 2022 to extend the performance range to 5000Nm.

The ROFLEX is a short shaft coupling in which input and output shafts can be pushed together between 3 and 6mm, depending on size. The torque is transmitted via elastomer packages, which at the same time compensate for misalignments and dampen shocks and torsional vibrations. Should the elastomers fail due to extreme loads, the fail-safe coupling continues to hold the torque.

The ROFLEX is made of grey cast iron and is available in two types: In type N, both the pocket and the cam part consist of standard hubs. In the SH SPLIT design the cam hub is split. Here, the hub is specifically and mechanically separated into two halves by fracture cutting, or cracking. The resulting fracture surfaces centre both hub halves precisely with each other, which makes incorrect assembly almost impossible. The hub halves can be mounted on block, the fit of the bore remains unchanged. Depending on accessibility, the hub can be pushed on for assembly. Or the two hub halves can be joined around the shaft; thus the split hub can be radially installed and removed without dismantling the adjacent units.

Michael Brüning, product manager at KTR, explains: "As a rule, we recommend that our customers fit the SH-SPLIT hub onto the motor shaft. This makes the coupling easier to assemble overall and in case of service there is more space available, for example to exchange the elastomer packs. In addition, it allows the user to carry out the direction of rotation check on the engine without the coupling hub."

The ROFLEX has been assessed and confirmed according to the European ATEX product directive 2014/34/EU and is suitable for use in potentially explosive atmospheres. Core industries are pumps and compressors; other areas of application in general mechanical engineering are gearboxes, fans and belt drives.

For further product information, visit: https://www.ktr.com/uk/products/roflex-failsafe-shaft-couplings/

https://www.youtube.com/watch?v=mOw6cARhjic

- No related articles listed