|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Cutting systems | >Cutting solutions on show |

Cutting solutions on show

27 July 2018

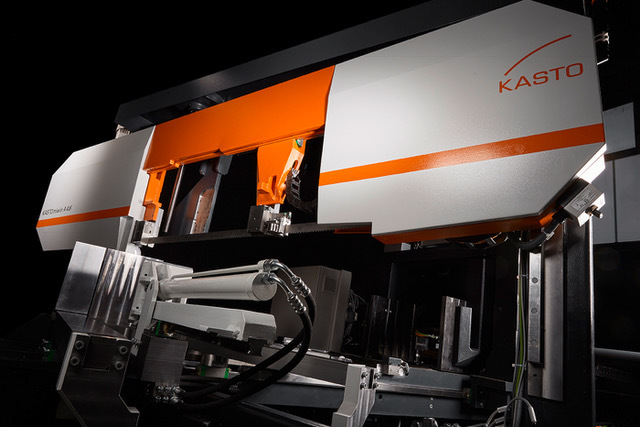

KASTO will be exhibiting at AMB, an exhibition for metalworking (18th to 22nd September, Stuttgart). Visitors can view the new KASTOmiwin bandsaw series, new models for the KASTOmicut workshop saw family and the revised high-performance saws of the KASTOtec series.

Solutions such as the universal sawing machines of the KASTOwin family, the UNITOWER compact tower storage system with energy recovery and the KASTOspeed circular saw with robot connection will also be on display in Hall 8 at booths 8B11 and 8B12.

With the KASTOmiwin, which premiered at KASTO FutureDays 2018, the Achern-based company is supplementing its range with a brand-new double mitre bandsaw for cut-to-length and mitre cuts between -45 and +60°. Initially available as a semi-automatic KASTOmiwin U 4.6 and an automatic A 4.6 version, the KASTOmiwin is designed especially for parts cut to size in steel construction, the steel trade, plant construction and special machine construction. KASTO will also be offering the swing-frame bandsaws of the KASTOmicut series, especially designed for use in workshops. Users can choose between manually-operated, semi-automatic and fully automatic variants – and now they can select different cutting areas too, because KASTO has added three new models to the range: the KASTOmicut E 4.6 and the semi-automatic KASTOmicut U 4.6, which have a particularly large cutting range, and the compact KASTOmicut P 1.8 for smaller workpieces.

KASTO will also be introducing something new in the field of high-performance saws for large series, because it has revised its KASTOtec range of bandsaws. Here the company’s designers focused on the best use of carbide saw blades. Using the intuitive control system, the operator can adjust all the parameters to match the type of bandsaw blade used. Depending on the blade, this can reduce cutting time by up to 50%. Another feature of the new KASTOtec is KASTOrespond. This intelligent system continuously records the forces on the tool without additional sensors and converts them into the optimal digital feed rate – the result is maximum performance which is also gentle on tools.

The leading saw technology company will also be showing the KASTOspeed, a high-performance automatic circular saw designed for cost-efficient mass production. This saw is said to excel in continuous operation; and a robot link can be used to easily integrate KASTOsort into a uniformly-controlled material flow. The KASTOspeed is available in two versions, for steel and for non-ferrous metals. Users can also choose between two sizes, with a cutting range of 90 or 153mm (in each case for round stock). The universal KASTOwin bandsaw will also be showcased at the exhibition. The KASTOwin bandsaws are said to offer a productive and economical solution for the mechanical engineering, toolmaking, steel trading and automotive industries, the aerospace technologies sector and many more.

Visitors to the AMB who are interested in the world of storage technology will see KASTO demonstrate the advantages of its compact UNITOWER tower storage system. This system is available in two different versions: UNITOWER for the storage of long workpieces and UNITOWER B for sheet metal, flat products and containers. The tower storage systems are designed as modular systems, so customised solutions can be realised with ease. Cassettes, pallets or supporting frames are used as the load carriers. Thanks to their variable loading height, these tower storage systems can save space and are said to be more economical than conventional floor and cantilever storage systems. The load carriers are handled by a storage and retrieval machine (SRM) an operating gantry crane with a central crossbeam loading traverse. Together with the efficient drives, this ensures fast access times and saves energy. KASTO's advanced conveyor systems and processing machines can also be used to connect storage and retrieval stations fully automatically, ensuring a highly-efficient and smooth internal material flow.

KASTO will also demonstrate its energy recovery and storage concept, using the UNITOWER storage system as an example. Surplus kinetic energy can be converted into electricity and stored temporarily for later use as needed. An intelligent controller charges and discharges the energy storage unit depending on what process is currently running. In this way users can reduce the connected load of the SRM operating gantry crane by an additional 50%, and they can use smaller transformer stations in their planning. This reduces operating and investment costs. Existing KASTO storage systems can also be retrofitted with energy recovery and storage.

- Steel stockholder speeds deliveries with new circular sawing machine

- Reliable feed process for heavy workpieces

- KASTO releases high performance saw

- Sawing & storage innovations

- Top end bandsaw

- Cutting aluminium blocks

- Warehouse upgrade

- Cuts cutting times by 50%

- Orders soar for sawing machines

- Robotic handling raises sawing productivity