|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Lubricants | >Perils of improper lubrication |

| Home> | Production Engineering | >Lubrication | >Perils of improper lubrication |

Perils of improper lubrication

30 August 2018

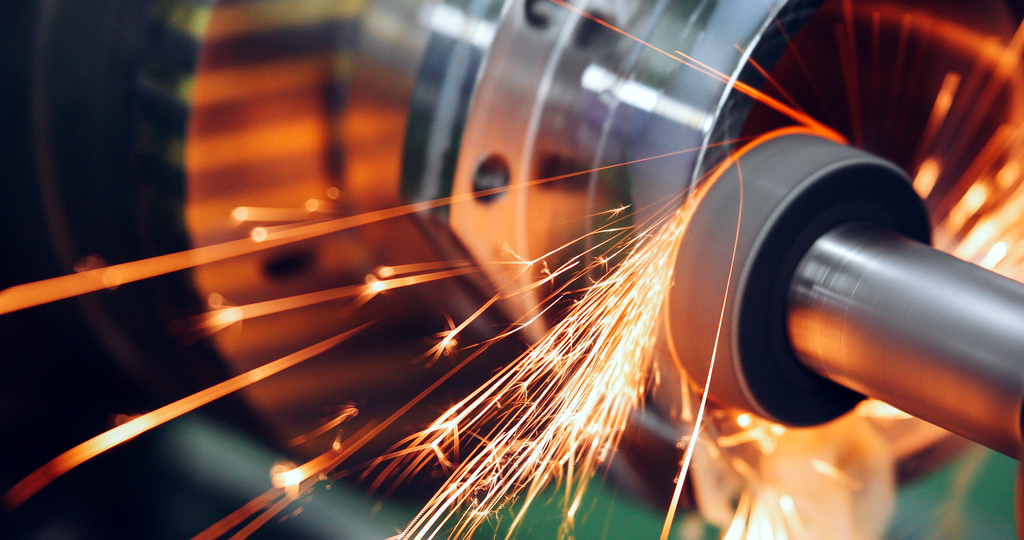

Bob Wood, technical engineer at Total Lubricants, reports that almost a third (28%) of industrial equipment failure is a result of inadequate lubricant maintenance and incorrect lubrication, with the likely impact potentially running into millions of pounds for UK businesses.

Improper lubrication, including using the wrong oil or not using enough oil, leads to increased friction and greater wear, which can lead to breakdown and downtime, and can ultimately impact bottom lines.

Bob Wood estimates that on average just 1% of an industrial plant’s overall maintenance budget is allocated to lubricants: “The lubricants that industrial equipment requires to keep it operating smoothly represent a fraction of the cost of the equipment itself, however, it is important this vital maintenance function is undertaken, with condition monitoring for critical equipment, including oil analysis, vibration analysis and thermography, being carried out regularly.

“Almost a third of industrial equipment failure, and the associated costs from unplanned downtime and reactive maintenance, could be prevented by having an effective and proactive lubrication strategy in place - It is better to identify problems before they occur, especially in large, industrial and manufacturing businesses, where the costs associated with downtime and lost productivity can run into the thousands, and potentially millions of pounds.

“We work closely with industrial businesses across sectors including metalworking, energy and food, to help them devise optimum lubrication strategies, and provide oil analysis, to help extend equipment lifetime, enhance productivity and improve health and safety.”

Total Lubricants offers a range of products developed specifically for over 400 industrial applications.

TOTAL VALONA HC is a range of neat cutting oils formulated exclusively from hydrocracked base oils. Transparent and odourless, its low volatility and high resistance to oxidation reduce misting and oil consumption due to evaporation, while extending tool lifetime.

The TOTAL MARTOL range of metal forming oils are chlorine-free, while being suited to the most demanding metal forming operations.

TOTAL ANAC INDUS is Total’s oil analysis service, which uses expert diagnostic and preventative information to help identify and prevent machinery health issues, and TIG 6, its optimised maintenance software for managing industrial lubricants.