|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >Explosion panels |

ARTICLE

Explosion panels

25 January 2013

Online pressure management specialist, ECODISC, has developed an explosion panel range to guard against the threat of explosion within silos and bucket elevators. Manufactured in accordance with industry legislation,

Online pressure management

specialist, ECODISC, has developed

an explosion panel range to guard

against the threat of explosion within

silos and bucket elevators.

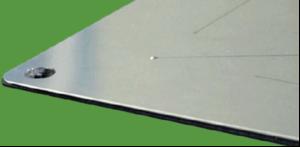

Manufactured in accordance with industry legislation, ECO Panel is designed to open at a pre-determined burst pressure and acts as an efficient and cost-effective means of protecting process plant.

ECO Panel is supplied in a number of standard sizes and with or without a frame, for maximum flexibility.

Available in stainless steel as standard with a cross-linked polyethylene foam back, the range is produced with ECODISC's advanced 3D laser cutting technology.

Manufactured in accordance with industry legislation, ECO Panel is designed to open at a pre-determined burst pressure and acts as an efficient and cost-effective means of protecting process plant.

ECO Panel is supplied in a number of standard sizes and with or without a frame, for maximum flexibility.

Available in stainless steel as standard with a cross-linked polyethylene foam back, the range is produced with ECODISC's advanced 3D laser cutting technology.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION