|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Lifting equipment | >Custom-solution sorts out 'snags' at STW |

ARTICLE

Custom-solution sorts out 'snags' at STW

25 January 2013

When engineers involved in a major Ajman (UAE) STW contract were closing down the final few snagging items, REID Lifting was asked to explore solutions for lifting blower motors installed in acoustic enclosures. The

When engineers involved in

a major Ajman (UAE)

STW contract were closing

down the final few snagging items,

REID Lifting was asked to explore

solutions for lifting blower motors

installed in acoustic enclosures.

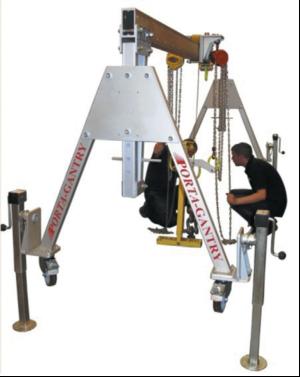

The Reid solution, a customvariant of its Porta-Gantry range, was designed such that the blower motors could be removed without dismantling the acoustic covers. The lifting gantry, being lightweight aluminium alloy, is portable and easily manually assembled. The design maximises every millimetre of headroom within the enclosure and includes wind-up jack legs that allow both coarse and fine adjustment in the height of lift. The system will be used across the suite of six blowers within the plant-room.

The equipment is installed and ready to use within 10min by just two maintenance operators and can also be used on other lifting tasks.

The Reid solution, a customvariant of its Porta-Gantry range, was designed such that the blower motors could be removed without dismantling the acoustic covers. The lifting gantry, being lightweight aluminium alloy, is portable and easily manually assembled. The design maximises every millimetre of headroom within the enclosure and includes wind-up jack legs that allow both coarse and fine adjustment in the height of lift. The system will be used across the suite of six blowers within the plant-room.

The equipment is installed and ready to use within 10min by just two maintenance operators and can also be used on other lifting tasks.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION