|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Cutting fluids | >Non-chlorinated cutting fluid |

ARTICLE

Non-chlorinated cutting fluid

25 January 2013

The R&D team at Master Chemical Europe has created TRIM E950, a boron and formaldehyde donor free, bio-stable cutting and grinding fluid. The lubricity of TRIM E950 is reported to ensure exceptional surface finish and

The R&D team at Master Chemical

Europe has created TRIM E950, a

boron and formaldehyde donor free,

bio-stable cutting and grinding fluid.

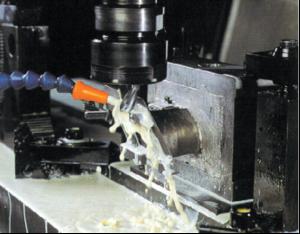

The lubricity of TRIM E950 is reported to ensure exceptional surface finish and tool life on difficult to machine aluminium alloys, inconel, titanium, stainless and high tensile strength steels.

These qualities make TRIM E950 particularly suitable for any industry where these materials provide qualities of low weight and high strength, such as aerospace, medical and motor sports.

The driving force behind the development of this premium emulsion product was to achieve the performance of previous generation highly chlorinated EP TRIM fluids without chlorine. The company says TRIM E950 has not just matched their performance, it has surpassed it, particularly with regard to tool life.

The lubricity of TRIM E950 is reported to ensure exceptional surface finish and tool life on difficult to machine aluminium alloys, inconel, titanium, stainless and high tensile strength steels.

These qualities make TRIM E950 particularly suitable for any industry where these materials provide qualities of low weight and high strength, such as aerospace, medical and motor sports.

The driving force behind the development of this premium emulsion product was to achieve the performance of previous generation highly chlorinated EP TRIM fluids without chlorine. The company says TRIM E950 has not just matched their performance, it has surpassed it, particularly with regard to tool life.

MORE FROM THIS COMPANY

- Low foam fluid

- Magnesium specific fluid

- Aerospace coolant

- Boron & formaldehyde free

- Metalworking oil

- No compromise coolant for the toughest of applications

- Locally produced metalworking fluids support Turkish manufacturers

- Long life parts washer

- Low-foaming, ferrous semi-synthetic coolant

- Renewable cutting oil

OTHER ARTICLES IN THIS SECTION