|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Infrared drying boosts corrugator capacity |

ARTICLE

Infrared drying boosts corrugator capacity

25 January 2013

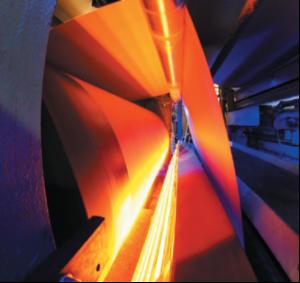

An infrared drying system from Heraeus Noblelight has helped DS Smith Tri-Wall to improve corrugator capacity of coated board at its factory in Monmouth and contributed to a reduction in downstream waste as well as a

An infrared drying system

from Heraeus Noblelight has

helped DS Smith Tri-Wall to

improve corrugator capacity

of coated board at its factory

in Monmouth and

contributed to a reduction in

downstream waste as well as

a decrease in energy usage.

Some of DS Smith Tri- Wall's markets require packing cases to be coated with an acrylic coating, to aid water resistance and to improve cosmetic appearance. Faced with the need to increase output of coated corrugated board, DS Smith investigated ways of increasing the running speed of the coated board drying section. Heraeus Noblelight carried out on-site tests using portable rapid response carbon medium wave infrared heaters.

These proved successful and a full-scale 56kW carbon infrared heating system was installed. This offers a total heated length of 2500mm and can be manually or automatically operated. There is a built-in facility to upgrade the system to 70kW if required.

Some of DS Smith Tri- Wall's markets require packing cases to be coated with an acrylic coating, to aid water resistance and to improve cosmetic appearance. Faced with the need to increase output of coated corrugated board, DS Smith investigated ways of increasing the running speed of the coated board drying section. Heraeus Noblelight carried out on-site tests using portable rapid response carbon medium wave infrared heaters.

These proved successful and a full-scale 56kW carbon infrared heating system was installed. This offers a total heated length of 2500mm and can be manually or automatically operated. There is a built-in facility to upgrade the system to 70kW if required.

MORE FROM THIS COMPANY

- Gas catalytic infrared oven installed for customer trials

- Heating systems on show

- Pizza problem solved

- Chocolate moulds get pre-heat treat

- Infra-red drying

- IR heating systems

- Warmth for cold steel

- Thermal endurance test rig relies on infrared system

- Carbon infrared heating system

- Carbon infrared oven saves time and space

OTHER ARTICLES IN THIS SECTION