|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >IR heating systems |

ARTICLE

IR heating systems

25 January 2013

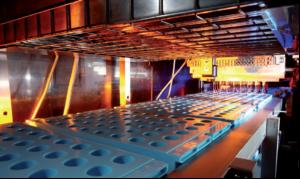

Two carbon infra-red heating systems from Heraeus Noblelight are helping to ensure consistent chocolate quality at Kinnerton Confectionery. One is used to pre-heat chocolate moulds prior to filling; the other to melt

Two carbon infra-red heating

systems from Heraeus

Noblelight are helping to

ensure consistent chocolate

quality at Kinnerton

Confectionery. One is used to

pre-heat chocolate moulds

prior to filling; the other to

melt chocolate rims prior to

rim heating, which involves

the fusing of two chocolate

halves. Both retrofitted

systems have provided space

and energy savings.

It is important that moulds are pre-heated to a specific temperature before chocolate is poured. If they are too warm, the chocolate can change its characteristics and detemper. Too cold and the poured chocolate will lose shape and possibly crack.

Heraeus Noblelight provided a trial infrared system. This proved a success and a full-scale 14.4kW carbon infrared system was installed, with a pyrometer to ensure that moulds are heated to exactly 29°C. A 9.6kW carbon infra-red system was then installed for rim heating.

The controllable heating system has significantly reduced reject levels.

It is important that moulds are pre-heated to a specific temperature before chocolate is poured. If they are too warm, the chocolate can change its characteristics and detemper. Too cold and the poured chocolate will lose shape and possibly crack.

Heraeus Noblelight provided a trial infrared system. This proved a success and a full-scale 14.4kW carbon infrared system was installed, with a pyrometer to ensure that moulds are heated to exactly 29°C. A 9.6kW carbon infra-red system was then installed for rim heating.

The controllable heating system has significantly reduced reject levels.

MORE FROM THIS COMPANY

- Infrared suitability tested

- Short wave system

- Embossing improved with medium wave

- Print drying is just the ticket

- Lab relocates to Cambridge

- Infrared drying boosts corrugator capacity

- Infra-red heaters

- Carbon infrared oven saves time and space

- Speeds up heating

- Spirit firm toasts new cask end process

OTHER ARTICLES IN THIS SECTION