|

Edward Lowton

Editor |

|

ARTICLE

PASSING THE TEST AT IPSOL

25 January 2013

From its base in Nottingham IPSOL Energy provides product test, R&D and consultancy services in clean energy with particular emphasis on the Solar Photovoltaic market. IPSOL's Centre of Excellence includes test and measurement equipment based around MiniTec Profile System machine framing and building components.

From its base in Nottingham IPSOL Energy provides product test, R&D and consultancy services in clean energy with particular emphasis on the Solar Photovoltaic market. IPSOL's Centre of Excellence includes test and measurement equipment based around MiniTec Profile System machine framing and building components.

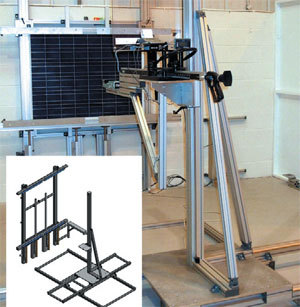

MiniTec's structural elements and machine frame hardware have been used for three IEC certification tests that each required the flexibility to cater for an assortment of solar panel types and sizes as the Unit Under Test, and provide a stable structure for measurement and test-support equipment. Tests included an enclosed 30m3 Soak Room where PV panel performance is measured, a UVDegradation test-stand, and Hail Test.

MiniTec worked with IPSOL, using its own in-house design service to develop 3D CAD concept drawings for each test-stand, which were then developed. IPSOL sourced and supplied third party components to MiniTec to ensure their correct installation and to coordinate electrical cabling requirements.

Rails, hardware and frame construction can be adapted during build.MiniTec's Powerlock fastening system is an effective frame connector that requires just the twist of an Allen key with no profile premachining. This makes profile re-use and adaptation possible with minimum cost and effort.

MiniTec's structural elements and machine frame hardware have been used for three IEC certification tests that each required the flexibility to cater for an assortment of solar panel types and sizes as the Unit Under Test, and provide a stable structure for measurement and test-support equipment. Tests included an enclosed 30m3 Soak Room where PV panel performance is measured, a UVDegradation test-stand, and Hail Test.

MiniTec worked with IPSOL, using its own in-house design service to develop 3D CAD concept drawings for each test-stand, which were then developed. IPSOL sourced and supplied third party components to MiniTec to ensure their correct installation and to coordinate electrical cabling requirements.

Rails, hardware and frame construction can be adapted during build.MiniTec's Powerlock fastening system is an effective frame connector that requires just the twist of an Allen key with no profile premachining. This makes profile re-use and adaptation possible with minimum cost and effort.

MORE FROM THIS COMPANY

- Profile of a safety system

- Profile system helps in quest for putting perfection

- Kanban storage

- Trolley service for turbo firm

- Profile systems

- Matching modular elements

- Aluminium profiles used for Office Cube

- Aluminium profile systems: New app available

- Mini framing profile with matching component range

RELATED ARTICLES

- No related articles listed

OTHER ARTICLES IN THIS SECTION