|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Carbon infrared heating system |

ARTICLE

Carbon infrared heating system

25 January 2013

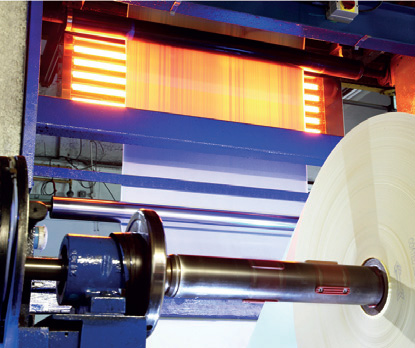

A carbon infrared heating system from Heraeus Noblelight is reported to have enabled Smith & Mclaurin to more than double line speed and improve quality on one of its paper coating lines. One of Smith and McLaurin's

A carbon infrared heating

system from Heraeus

Noblelight is reported to have

enabled Smith & Mclaurin to

more than double line speed

and improve quality on one of

its paper coating lines.

One of Smith and McLaurin's products requires a water-based adhesive to be applied to high value stock before a laminate is applied to the adhesive. Previously, the adhesive was dried in a warm air oven but this sometimes caused problems when drying coloured adhesive.

To solve the problem Heraeus installed a 32.5kW infra-red heating system equipped with five carbon medium wave emitters immediately before the existing warm air heaters. The emitters are individually controlled so that they can be switched on and off according to the coating weight.

One of Smith and McLaurin's products requires a water-based adhesive to be applied to high value stock before a laminate is applied to the adhesive. Previously, the adhesive was dried in a warm air oven but this sometimes caused problems when drying coloured adhesive.

To solve the problem Heraeus installed a 32.5kW infra-red heating system equipped with five carbon medium wave emitters immediately before the existing warm air heaters. The emitters are individually controlled so that they can be switched on and off according to the coating weight.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION