|

Edward Lowton

Editor |

|

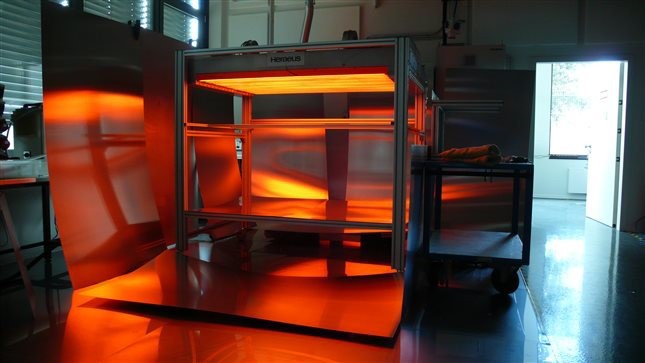

Infrared module hastens heating

05 July 2017

A solid reflector infrared module (SRM) from Heraeus Noblelight is designed to speed up heating or improve quality in the processing of thin and sensitive materials such as textiles or tissues.

Its special construction, incorporating external, top-mounted radial fans, air inlets and outlets, eliminates any air movement over the substrate to be heated, avoiding heat losses due to convection and any possibility of thermal shock.

The SRM has an internal reflector sheet and at least one carbon infrared (CIR) emitter, fitted with its own Gold- or Quartz- Reflective Coating (QRC) reflector, is mounted in front of the reflector sheet. Developed by Heraeus, the coating of QRC reflectors features a special nano- and microstructure which is said to provide very high diffusion reflection characteristics to ensure the stability of process parameters, such as temperature and coating homogeneity.) Gold reflectors can be used for power densities to 50kW/m2, while QRC reflectors are suitable for power densities to 70kW/m2. The complete module is air-cooled by radial fans mounted on its top side and a series of baffles prevents any cooling air from contacting the substrate to be heated.

Typical applications include homogenous heating of materials of low thermal conductivity, heating of thermally sensitive materials such as textiles and plastic foils, heating of composite materials both carbon and glass fibres, fusing of polymer and synthetic materials and curing of resin systems.

- IR drying systems cuts cost on coating line

- Gas catalytic infrared oven available for trials

- Infra-red heating system

- Fast response infrared heating system

- Gas catalytic infrared oven installed for customer trials

- Queen’s Award For Enterprise winner

- Pizza problem solved

- Infrared suitability tested

- Dry inks at high speed

- Compact infrared print dryer