|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >IR machine vision |

ARTICLE

IR machine vision

04 March 2013

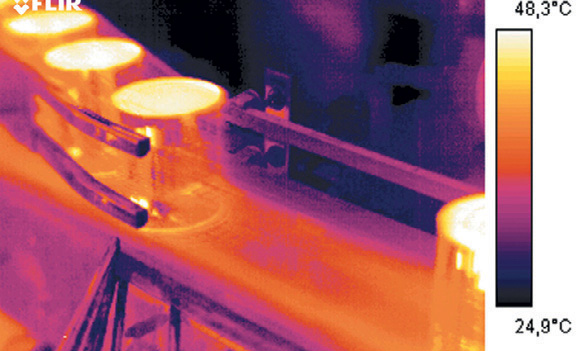

Operating without the need for additional lighting, FLIR thermal machine vision systems such as the new, uncooled A65 provide a high degree of intelligence in automated environments, for example in confirming cure temperatures.

Operating without the need for

additional lighting, FLIR thermal

machine vision systems such as the

new, uncooled A65 provide a high

degree of intelligence in automated

environments, for example in

confirming cure temperatures.

The compact A65 provides high image quality. Integration into existing production systems is quick and easy due to a range of in-built connectivity options. The camera produces crisp thermal imaging from 640 x 512 pixels across -40 to 550°C.

The compact A65 provides high image quality. Integration into existing production systems is quick and easy due to a range of in-built connectivity options. The camera produces crisp thermal imaging from 640 x 512 pixels across -40 to 550°C.

MORE FROM THIS COMPANY

- Worldwide MSX demand fuels cost reduction

- Cabinet monitoring solutions designed to cut inspection time

- Infrared windows range extended to include a stainless steel version

- Training courses

- FLIR announces 2020 dates for Category 1 thermography course

- Low on price

- Seeing infrared

- Compact camera

- Thermal imaging: Webinar date

- In the picture on turbine issues

OTHER ARTICLES IN THIS SECTION