|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >Pilz to make virtue of scalability at Total 2013 |

ARTICLE

Pilz to make virtue of scalability at Total 2013

17 April 2013

Machine safety experts will be on-hand throughout the show to discuss functional safety-related control solutions, standards and training courses for process and packaging applications found in the food, beverage, tobacco, pharmaceutical and other industrial sectors.

Machine safety experts will be

on-hand throughout the

show to discuss functional

safety-related control solutions,

standards and training courses for

process and packaging applications

found in the food, beverage, tobacco,

pharmaceutical and other industrial

sectors.

Pilz offers harmonised and complete safety automation solutions for primary, secondary, end-of-line packaging machinery and other related processing machines, regardless of machine or installation size. The machine safety experts also offer consultancy from initial plant or machine risk assessment through to engineering, plus training or in-house support.

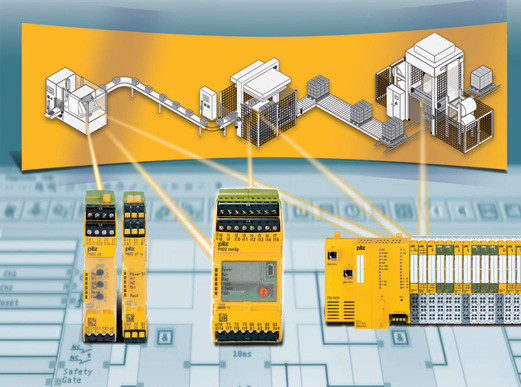

Stand hardware highlights will include the new PNOZmulti 2 configurable safety control system, the IP67 rated Pilz Decentralised Periphery (PDP) safe distributed I/O solution for 'cabinet-free connectivity', the PSS4000 integrated standard and safety automation system and the latest developments in the Pilz range of safety interlocks, RFID-based sensors, access control devices and light curtains. Details of newly developed training courses will also be available.

Stand G16

Pilz offers harmonised and complete safety automation solutions for primary, secondary, end-of-line packaging machinery and other related processing machines, regardless of machine or installation size. The machine safety experts also offer consultancy from initial plant or machine risk assessment through to engineering, plus training or in-house support.

Stand hardware highlights will include the new PNOZmulti 2 configurable safety control system, the IP67 rated Pilz Decentralised Periphery (PDP) safe distributed I/O solution for 'cabinet-free connectivity', the PSS4000 integrated standard and safety automation system and the latest developments in the Pilz range of safety interlocks, RFID-based sensors, access control devices and light curtains. Details of newly developed training courses will also be available.

Stand G16

MORE FROM THIS COMPANY

- PNOZ m C0 - as narrow as a safety relay, but as powerful as a safety controller

- Machinery safety

- Machinery safety: Course announced

- Sharing knowledge

- 360° approach to machinery safety

- Safe human-robot collaboration

- Supply & support

- Interactive PUWER inspection

- All-in-one safety gate

- Make the world a safer place - enhance your Machinery Safety knowledge with the best in industry

OTHER ARTICLES IN THIS SECTION