|

Edward Lowton

Editor |

|

| Home> | Handbooks | >Manufacturing Matters Ireland | >High pressure cooling |

| Home> | Plant, Process & Control | >Pumps | >High pressure cooling |

High pressure cooling

07 November 2013

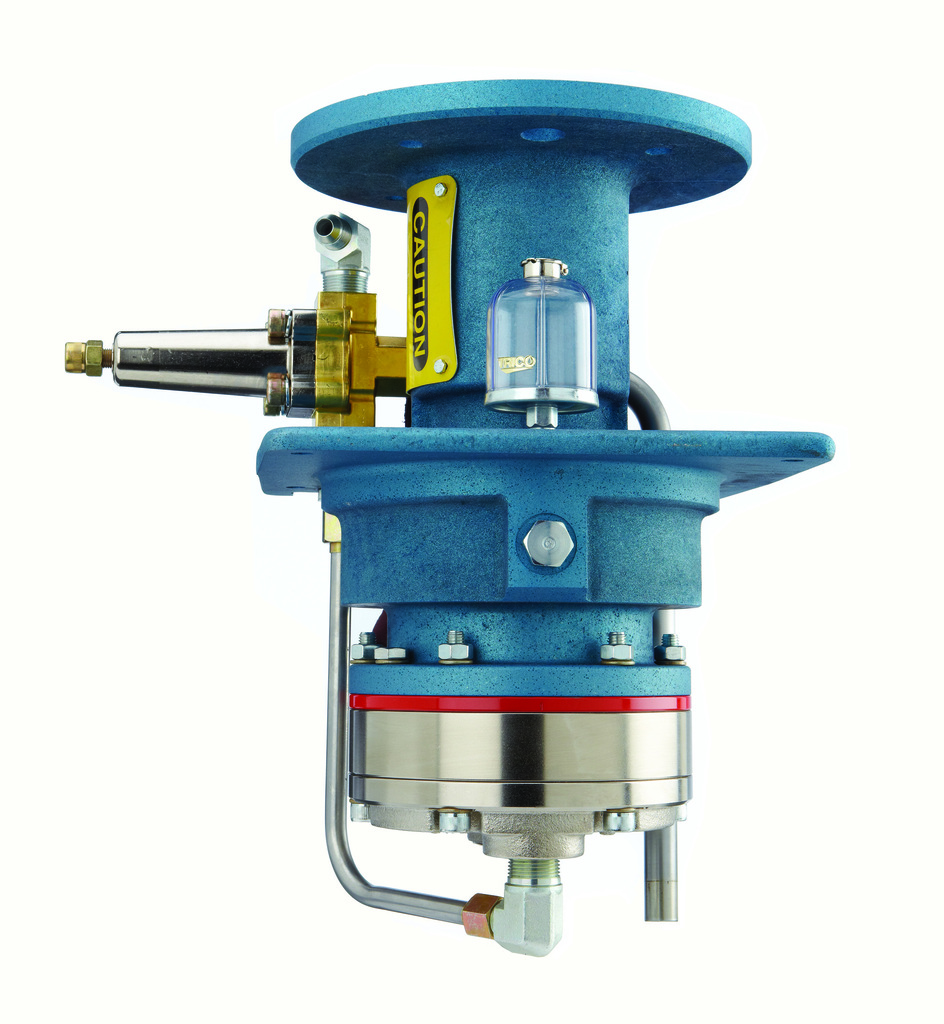

Many pump types offer the pressures and flows required for high pressure coolant delivery but, says Wanner, few claim the reliability performance of Hydra-Cell hydraulically balanced diaphragm pumps.

High pressure coolant delivery (to 170 Bar) offers benefits in terms of metal cutting efficiency. It can offer reductions in cycle time of up to 70% while improving the quality of surface finish, extending the life of tooling and inserts, and enhancing chip control.

Machining produces fines as well as chips – small particles of metal that are highly abrasive. Wanner says that if these are not removed from the system by ultra-fine filtration they will eventually destroy any pump where bearings and seals are exposed to the pumped coolant.

Hydra-Cell hydraulically balanced diaphragm pumps handle fines over 500mµ in diameter, removing the need for fine filtration.

- Eliminates leaks

- Energy efficiency in high pressure coolant delivery

- On show at Achema

- New higher pressure Hydra-Cell high horsepower pumps

- High horsepower pumps achieve ATEX certification.

- Cut out for chemical dosing

- Run-dry pumps handle aggressive chemicals

- Dosing range

- Low life-cycle costs

- Easy access for service