|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Cables, connectors and energy chains | >Tested to last |

ARTICLE

Tested to last

22 January 2014

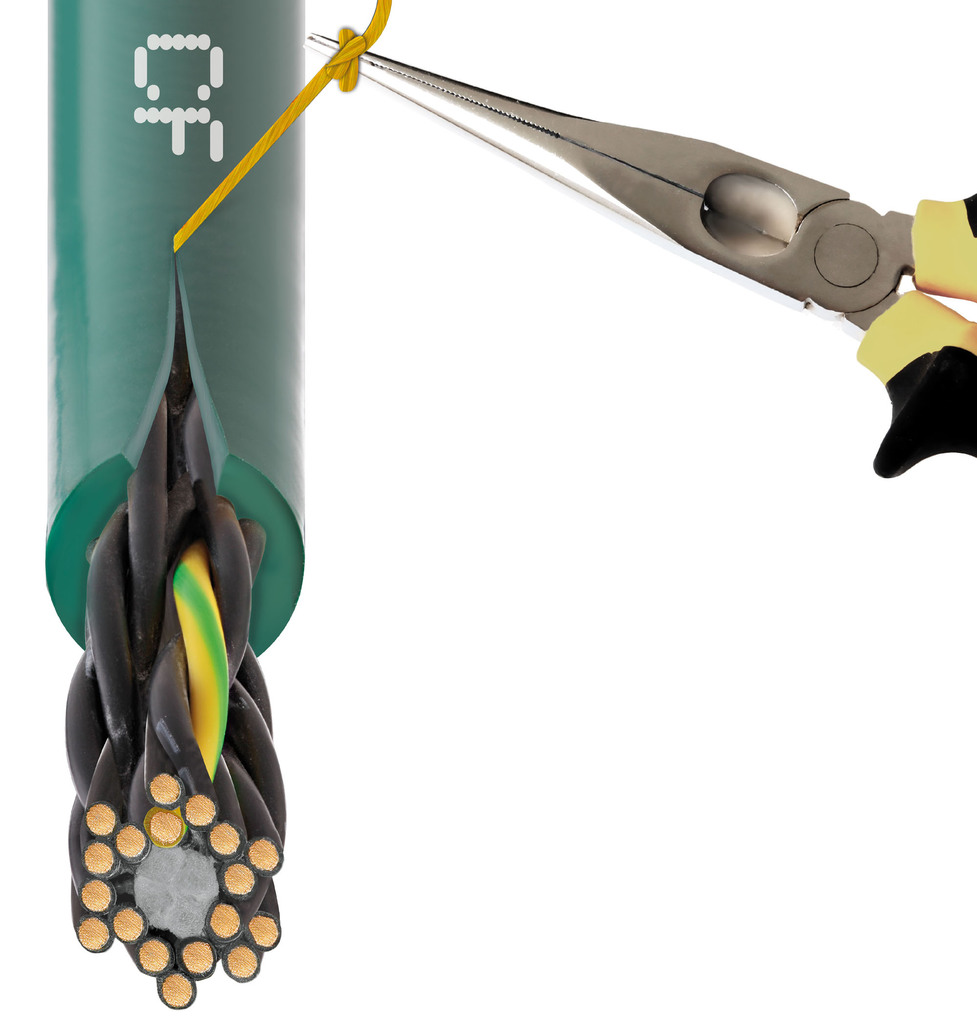

Requirements for the safe and reliable supply of moving power and data in today’s sophisticated machines are becoming more and more stringent. To meet such demands, igus ensures that all of its continuous-flex cable solutions undergo extensive testing in its state-of-the-art laboratories in Cologne.

All igus cables are tested in challenging real-life cable environments, involving chemical and environmental resistance as well as bespoke customer specific tests. Not only does the test laboratory perform more than 600 parallel running tests at any one time, it also runs more than two billion test cycles per year.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION