|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Motors and drives | >Energy costs cut |

ARTICLE

Energy costs cut

24 March 2014

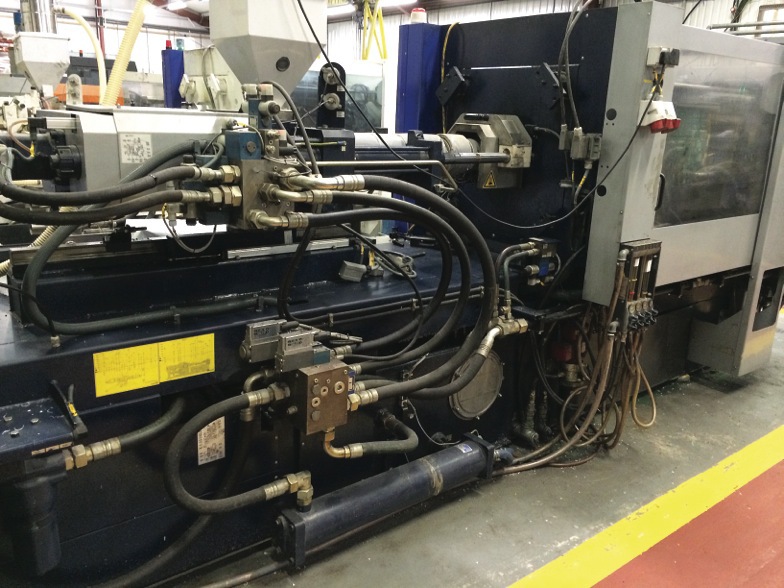

Manufacturer of water fittings and valves, Atlantic Plastics, is reported to be saving 20% of the energy costs of a large injection moulding machine, following the fitting of an ABB variable-speed drive.

Gary James, engineering manager identified two 400t injection moulding machines as particularly energy intensive, so he approached ABB authorised value provider APDS for a solution.

An investigation showed that the existing direct-on-line installation used 25.3kW. APDS installed a trial drive at the site to measure the actual demand required and match the flow to this demand. This drive drew 10.5kW, giving an average hourly saving of £1.28 in electricity costs.

MORE FROM THIS COMPANY

- Electrical supply upgrade avoided

- Automation system enhanced

- Industrial flow measurement: Handbook updated

- ABB technology to help tackle methane leakages from orphan oil and gas wells

- VSDs: An energy-saving case

- Rapid growth of Safety Execution Centers

- VSDs for fast pump testing

- Winner of the EEF Green and Growth Award

- Quick & easy temperature instrument selection

- ABB to host workshops

OTHER ARTICLES IN THIS SECTION