|

Edward Lowton

Editor |

|

ARTICLE

Beko Owamat

15 May 2014

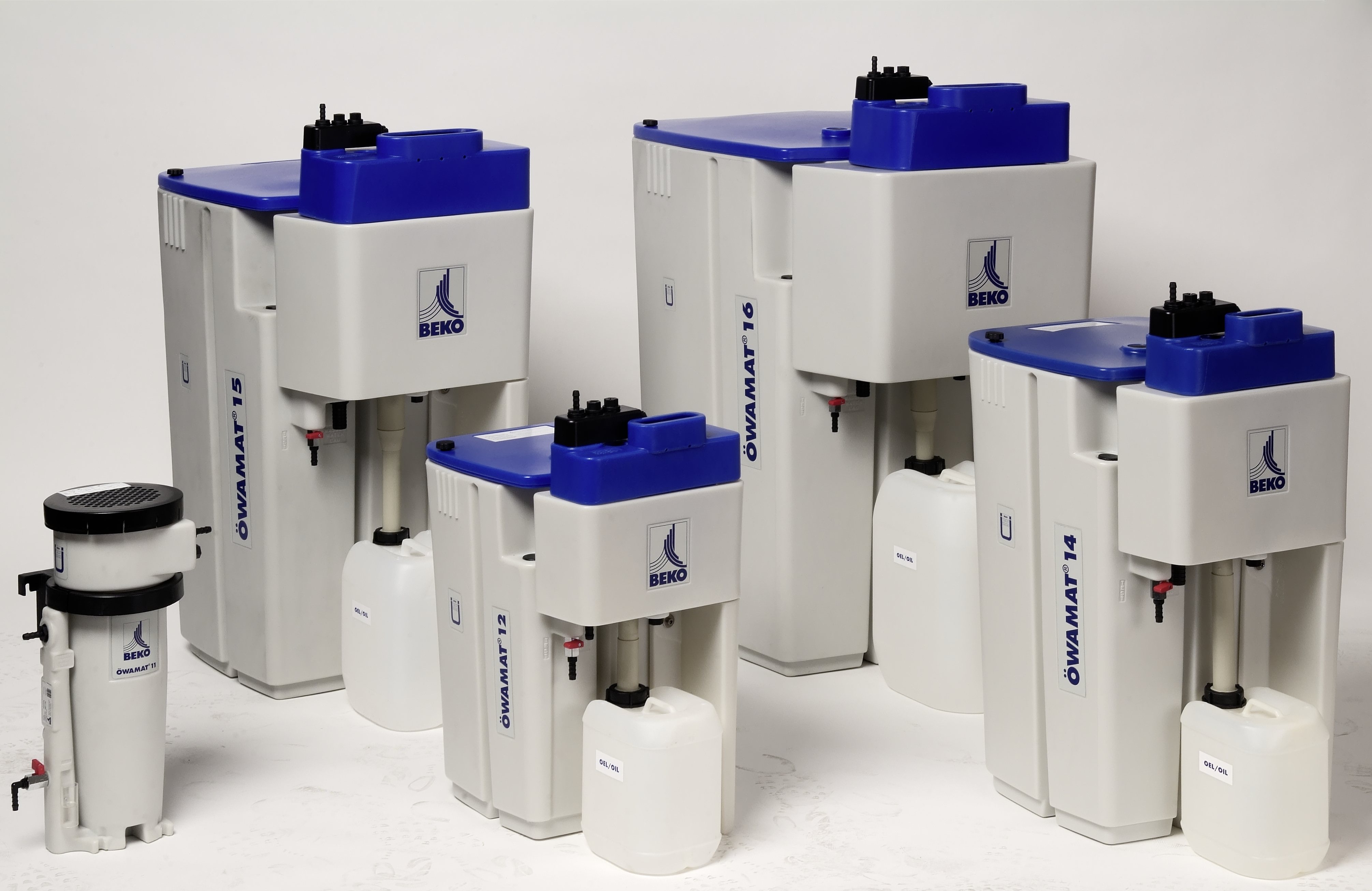

Reliably separated, efficiently processed Oil-water separation with ÖWAMAT®

The concept: sustainability with a savings potential. The solution: ÖWAMAT®

From the process plant control to pneumatic test and control methods – in large parts of production, compressed air has become indispensible. However, during its generation, contaminated condensate is formed which contains, for example,hydrocarbons, dust and dirt particles from the intake air, coolants and lubricants from the compressor, as well as oil residues, rust, wear debris or residues from sealants.

Cost factor disposal

Condensate, as an oil-containing wastewater, must not be introduced into the sewer system according to the Federal Water Act, meaning that the condensate either needs to be disposed of professionally or processed on location. Disposal via external service providers is an expensive process. In addition to the disposal costs, company-internal investment costs, for example for approved collection tanks and monitoring devices, are incurred.

What remains, counts: ÖWAMAT® ensures oil-free wastewater

A more cost-effective solution for environmentally compatible condensate management is the decentralised processing of dispersed condensates directly at the source. For this, ÖWAMAT® oilwater separators made by BEKO offer a clean solution: condensate which was processed using an ÖWAMAT® can be directly introduced into the sewer system as purified water. The units meet all legal requirements. Furthermore, ÖWAMAT® oil-water separators do not cause any energy costs, boast enormous service lives and therefore, the cartridge disposal involves only little waste. The devices can be retrofitted without problems in older plants. With this, ÖWAMAT®meets highest requirements on sustainability, efficiency and profitability.

For more information on BEKO ÖWAMAT® please CLICK HERE.

MORE FROM THIS COMPANY

- White paper on food safety

- Ongoing quest to prevent oil contamination of foods

- Free e-learning ' Basics of compressed air' course

- Catalytic converter

- Win an iPad with Beko Technologies

- Trend towards measurement

- Bacteria and condensate

- Online calculation tool

- Free compressor check

- Come and see Beko Technologies at Air-Tech 2016

RELATED ARTICLES

- No related articles listed

OTHER ARTICLES IN THIS SECTION