|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >Safety gate switches: Configuration aid |

Safety gate switches: Configuration aid

09 July 2014

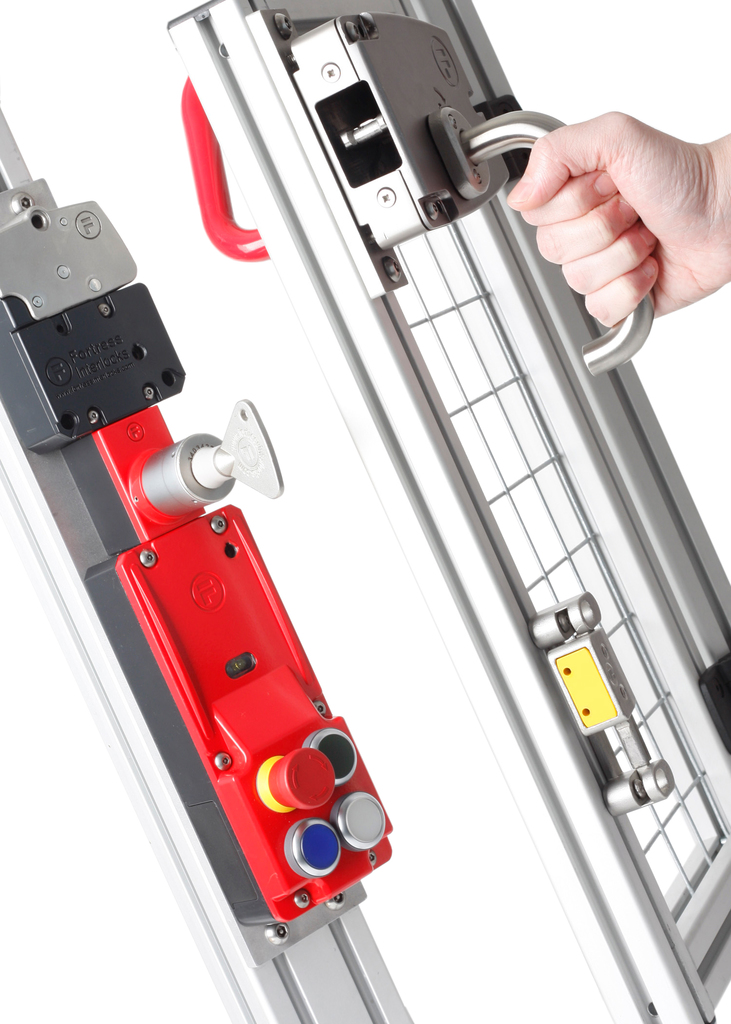

amGard pro is Fortress Interlocks’ modular interlock range for safety gate switches for heavy duty applications. Its modular construction (made up of actuators, head modules, adaptors, electrical switches/locks and optional push-button pods) allows easy configuration for virtually any safeguarding application to SIL3 (EN/IEC 60261) Category 4 and PLe (EN/ISO 13849-1).

Fortress now has a Product Configurator on its website and, by following the simple steps described, users can configure a complete unit, with part numbers, an image, a 2D drawing and a 3D model.

The amGard pro offers a range of fully integrated safety interlocks, including solenoid and non-solenoid safety switches with many additional options including key control modules, emergency release, redundant sensors, lock out/tag out and push buttons, e-stops and indication lights for enhanced functionality. Robust construction makes it suitable for industrial applications when safety, strength and reliability are of paramount importance.

Additional hardware such as door catches, actuators, closing mechanisms, internal release mechanisms, key functions including authorised access and deadlocks are no longer needed. All of these separate functions can be incorporated into amGard pro configurations, resulting in a very flexible safety interlock solution.

Key features of the amGard pro including:

• Enhanced machine control functionality

• Integrated pushbutton control in a single unit

• Up to three illuminated pushbuttons/lamps/selector switches, plus one e-stop

• Up to 10 safety/access keys in one configuration

• Improved Standards compliance

• Complies with all new and forthcoming machine safety standards

• Integrated redundancy sensor (with coding options)

• Single motion emergency escape release regardless of solenoid or trapped key locking mechanism

• Enhanced strength

• Stainless steel heads with mounting point, increasing retention force to 10KN

• Standardisation and enhancement of all anti-vibration features

• Improved weather resistance

- Extracted key adaptor ensures machine safety

- Perimeter guarding

- Alliance member

- Switchgear interlock

- Customisable access control

- Ethernet communications for interlocks

- Sharing machine safety knowledge

- Key exchange unit with integrated switch function

- Modular stop

- Fitting safety switches to machine guarding