|

Edward Lowton

Editor |

|

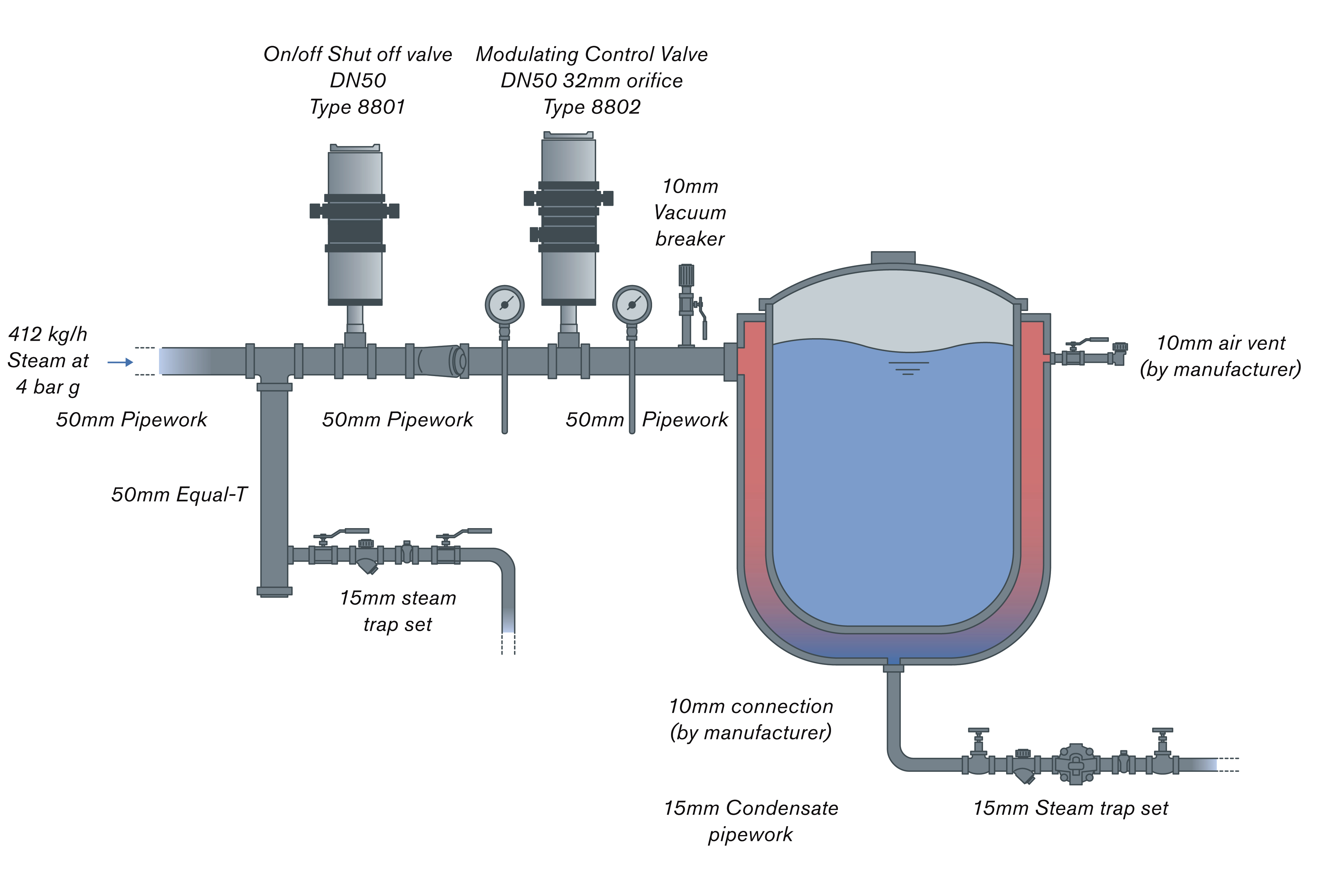

Correct sizing of pipework and valves for steam applications ensures reliable and efficient operation.

07 August 2014

Steam is used in a wide range of industries for a variety of processes, from a basic small heating circuit to large scale hygienic steam production, involving specialist equipment which needs to be designed and maintained properly to ensure efficient and reliable operation of the process equipment.

Ian Webster, Hygienic Processing Segment Manager at Bürkert UK offers industry leading steam training courses; here he looks at some of the basic calculations that should be understood by design and maintenance engineers in order to achieve a safe and efficient process.

‘Modern production environments require the maintenance team to be experts in a vast range of fields and while many areas may be adequately covered, steam equipment can sometimes be overlooked. This can lead to costly breakdowns or repairs which could have been avoided if some basic principles were better understood.’

Initially, it is important to understand a few basic principles, such as pressure measurement, which in the main, is quoted as gauge pressure, which reads zero at ambient air pressure and would be displayed as 3 bar(g) for example.

Please click here to view this press release in full.

- How data can improve maintenance engineering

- Solenoid valves: An enduring design

- Pumps firm appoints account manager

- Controlling hydrogen in fuel cells

- Sense and sensitivity

- Simplifying industrial process automation with IO-Link

- Online monitoring optimises water quality

- Monitoring enhances accuracy and predictive maintenance

- Countering contaminants

- Precision water quality analysis