|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Quality and tolerance testing | >Finite element analysis |

Finite element analysis

28 January 2015

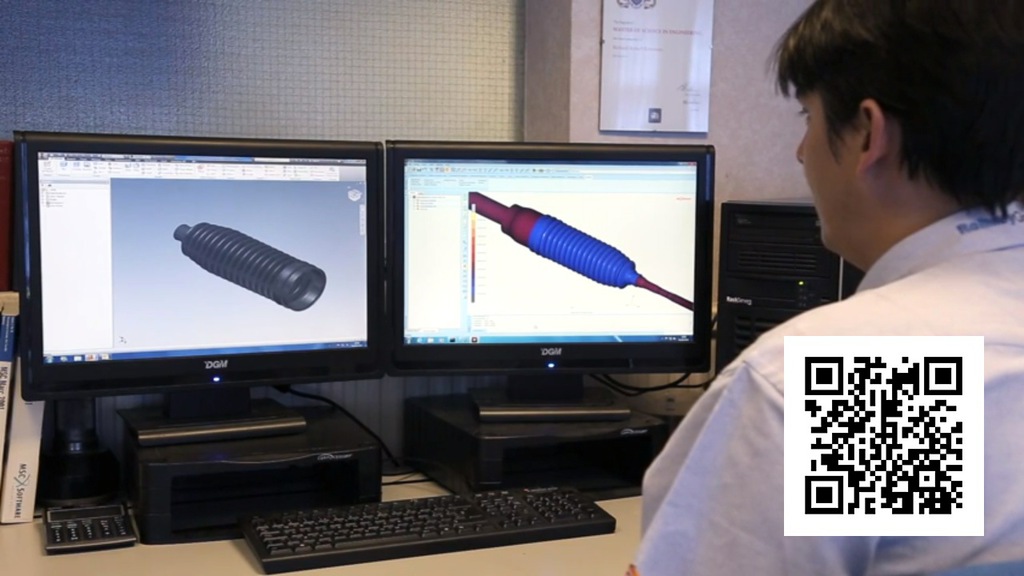

Expert in Finite Element Analysis (FEA), Blue Diamond has produced a short video to show how this advanced engineering tool can be used to aid design and to minimise the need for experimental testing. Just go to YouTube and enter “Blue Diamond Technologies FEA”.

FEA allows the user to predict and improve product performance and reliability, make physical prototyping more accurate, evaluate different designs and materials whilst also reducing material usage and cost.

The effects of wear can be assessed in a virtual environment as can the application of constraints such as pressure and temperature. Tolerances in the component or assembly can be readily identified in order that any play or movement can be accommodated within the final design.

The company is exhibiting at Southern Manufacturing on stand U115.