|

Edward Lowton

Editor |

|

Biggest order for press brakes

17 February 2015

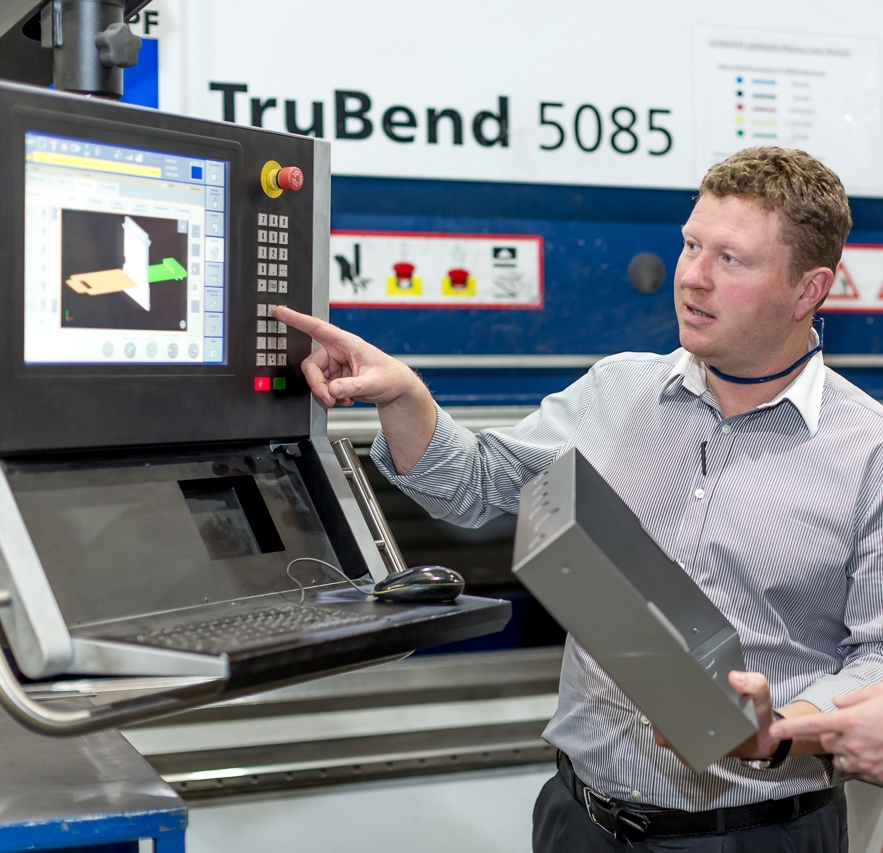

TRUMPF UK has received its biggest ever order for CNC press brakes. A total of nine TruBend Series 5000 press brakes have been ordered by KMF, a sheet metal subcontractor based at Newcastle-under-Lyme.

Keith Nicholl, business improvement manager at KMF, explains: "The decision to purchase the TRUMPF press brakes was taken after a number of reviews with our folding team. We examined the key elements and features that needed to be present in our production environment, which is strictly based on a made-to-order strategy, typically against small batch sizes and short lead-times.”

According to Nicholl, simplicity of set-up, speed of tool change and repeatability came out as the principal driving factors: "During trials, we found that the TRUMPF press brake could reduce a complicated multi-bend set-up from 40 to less than 5min. This, along with the confidence we have from our experience of using TRUMPF punch and laser systems, convinced us that this was the right choice for KMF.”

"KMF are looking to ensure that the press brake does most of the technical hard work,” states Paul Johnson, area sales manager at TRUMPF UK. "There are several aspects of TRUMPF press brakes that aid this strategy. For instance, operators are not only guided through the whole bending program using graphical instructions, but optical setting aids light up where the tooling should be placed. In addition, there are set access levels for different operators and setters, so programs can be pulled down, but not modified without authority. Historically, a press brake operator is one of the most skilled on the shop floor, but with TRUMPF technology the way that this skill set is utilised is changing.”

KMF has ordered seven 2.5m bed TruBend models (85t capacity) and two 3m bed models (130t capacity). All nine machines feature an extended open height for bending components such as deep boxes, and all offer tooling compatibility. One machine comes with TRUMPF’s bending aid, which reduces a two-man operation to a one-man function when handling large panels.

"Other features of the TRUMPF press brakes include hydraulic tool clamping (top and bottom), rapid bending speed and eco-friendly on-demand drives, which offer reduced power consumption,” says Johnson.