|

Edward Lowton

Editor |

|

| Home> | Handbooks | >Manufacturing Matters Ireland | >Hazardous-area safety light curtains |

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >Hazardous-area safety light curtains |

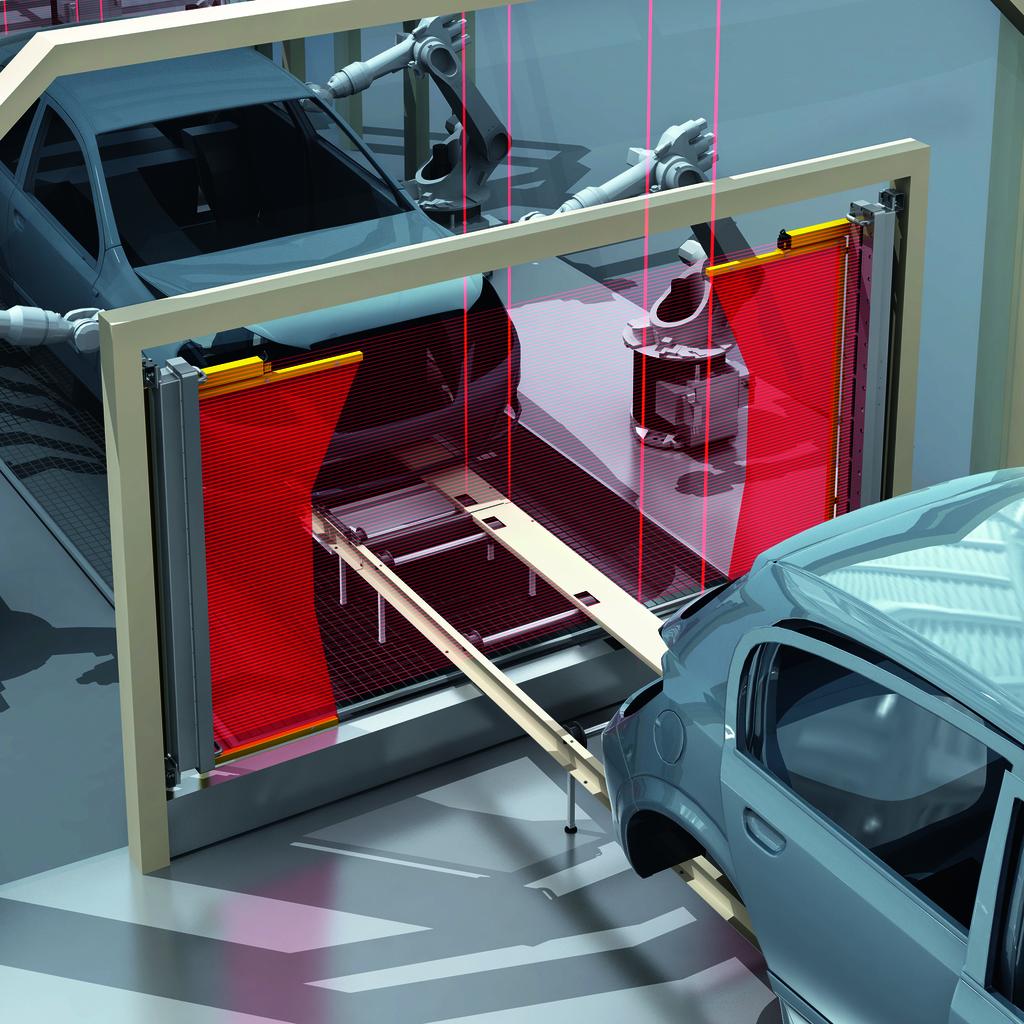

Hazardous-area safety light curtains

02 July 2015

By designing an explosion-proof enclosure for its light curtain technology to ATEX and UL Listed hazardous area standards, SICK is offering a high degree of safety protection for high risk flammable gas, vapour and dusty industrial environments.

The deTec4 Core Ex, C4000 Select Ex and C4000 Advanced Ex light curtains are all-in-one pre-assembled safety devices suitable for a range of hazardous environments from pharmaceutical, chemical and paint manufacture to food processing and storage, to gas and coal industries.

"This is the first time a true fit-and-forget safety light curtain solution has been available for ATEX and UL designated hazardous areas,” says Martin Kidman SICK (UK) machinery safety specialist. "There’s no assembly needed as the light curtain and enclosure have already been tested as a single unit and verified ready for use.

"Downtime is reduced and therefore all the dangers of starting and stopping critical processes to install safety light curtains to guard dangerous machinery and protect personnel are eliminated. The range of fields and enclosure sizes means all sorts of equipment can be easily protected.”

The deTec4 Core Ex, C4000 Select Ex and C4000 Advanced Ex safety light curtain models offer a range of protective field heights and can be combined to create 10 different variants within the rugged aluminium IP66 explosion-proof enclosure. Highly-visible LED status indicators ensure rapid troubleshooting.

Available in three different lengths, the enclosures can accommodate a number of light curtains allowing protective field heights of 600, 900, 1200 and 1500mm (only with deTec4 Core). With a resolution of 30 mm a scanning range of up to 16m can be achieved (depending on the model).

Both enclosures and light curtains are maintenance free and have a number of features to aid quick installation. The enclosures are supplied fully assembled and the light curtains are pre-wired into the enclosures to certified standards. Quick alignment mounting brackets enable rapid set-up and the optional laser alignment tool can make installation even easier. Removable handles are included with the enclosure for easy handling and positioning by installers.

The explosion proof enclosures for safety light curtains are available separately (Transmitter/Receiver) or as a pair and are supplied pre-wired and assembled so that specialist installation is not required. They are designed and approved for use in hazardous locations according to ATEX for gas: II 2 G Ex d IIB T6 Gb, for dust: II 2 D Ex tb IIIC T56°C Db. NFPA 70/NEC 500, Class I, Div. 1, groups C and D, Class II, Div. 1, groups E, F and G and Class III, Div. 1.

- Customisable sensors

- Linear positioning

- Vision-guided part localisation

- All-Purpose Proximity Sensing from SICK in One Second Flat

- Powerful and accurate 2D LiDAR sensor

- High-definition streaming camera

- Light curtain

- Safe network integration added

- Off-the-shelf label inspection solution

- All weather sensing