|

Edward Lowton

Editor |

|

Laser-based measuring

10 October 2015

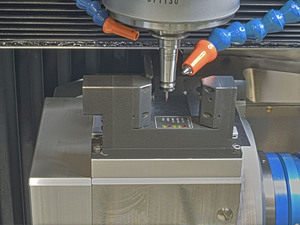

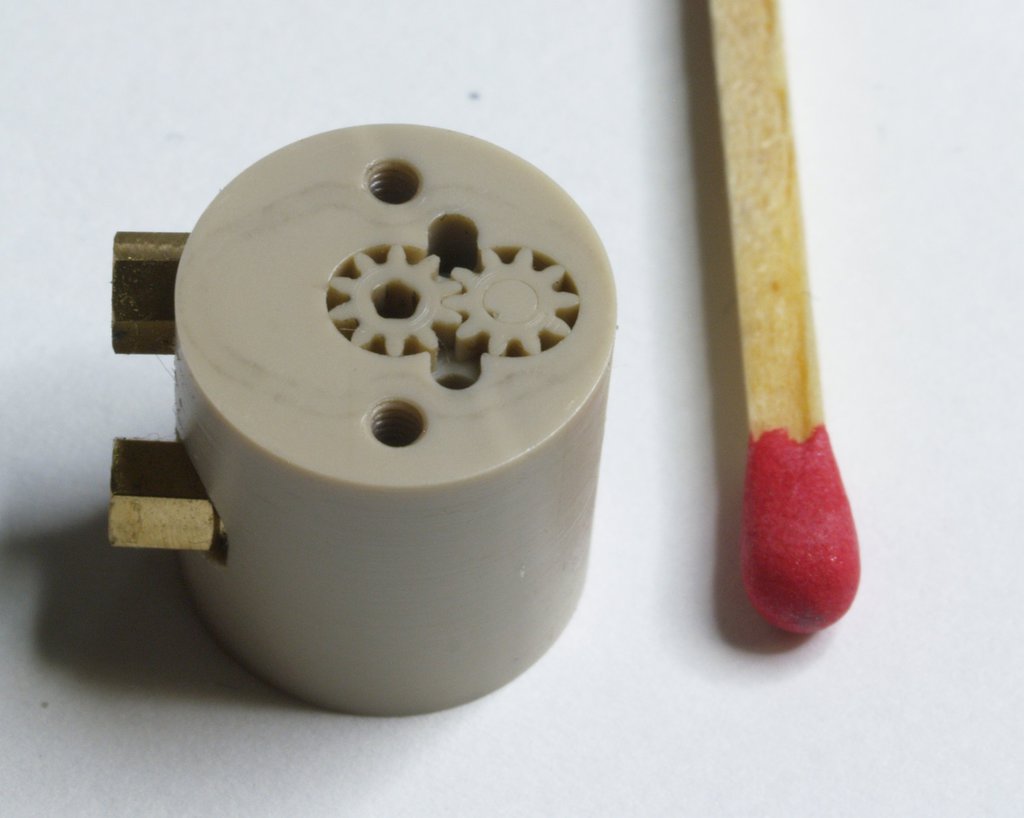

W Präzisionstechnik uses high precision five-axis milling machines to produce tiny components with high levels of accuracy. Laser-based measuring systems from Blum-Novotest are used for tool setting and breakage detection on these extremely sensitive tools.

As the LaserControl measurement systems have to be located in the working space in the machining centres, the optics need to be protected. Blum uses several methods to do this. The laser optics are mechanically protected by a shutter during machining.

When the shutter opens for measurement, a sudden blast of air is released to clear the device of dirt and chips. During measurement, a stream of barrier air reliably protects the optics from contamination to guarantee in-process reliability.

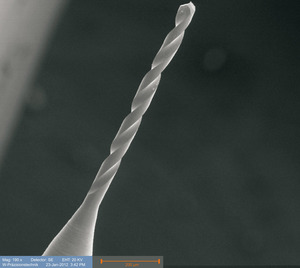

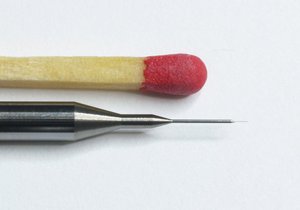

Unlike other laser measurement systems, the laser beam on the Blum devices is focused, in other words the beam is extremely thin at a particular point between the laser transmitter and receiver. The models in the Nano NT series reach a beam thickness of just a few microns.

On unfocused systems with a greater beam thickness, it is possible that the measuring system will "miss" the actual drill when determining the tool length and only detect the significantly thicker shaft. If these incorrect tool values are then used for milling, a tool breakage and a rejected workpiece are almost inevitable.

- No related articles listed